Best CNC Machines for Beginners [The Ultimate Guide]

What are CNC Machines

Automated systems that are used to control machinery tools through computer programming are termed CNC (Computer Numerical Control) machines. These machines take their applications in industries like precision machining and manufacturing processes.

Some common types of CNC machines and their applications include

- CNC Milling Machines:

- Used to remove material from a workpiece to create complex shapes and features.

- Applications: Prototyping, custom parts manufacturing, aerospace and automotive components, mould making, and more.

- CNC Lathe Machines:

- Used for cutting, drilling, and shaping cylindrical or rotational parts.

- Applications: Turning of shafts, bolts, screws, and other rotational components in industries such as automotive and aerospace.

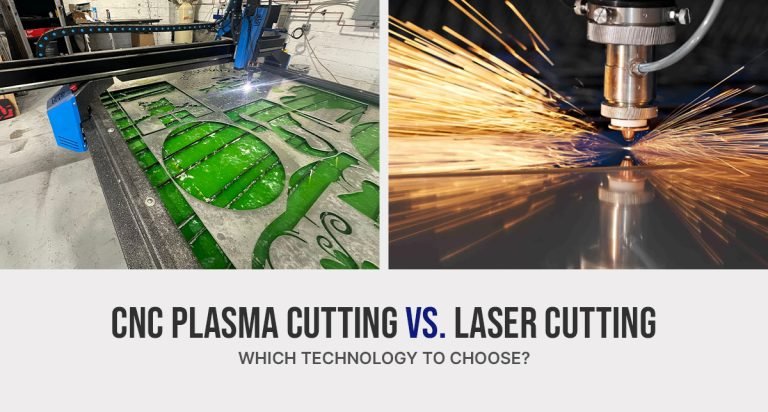

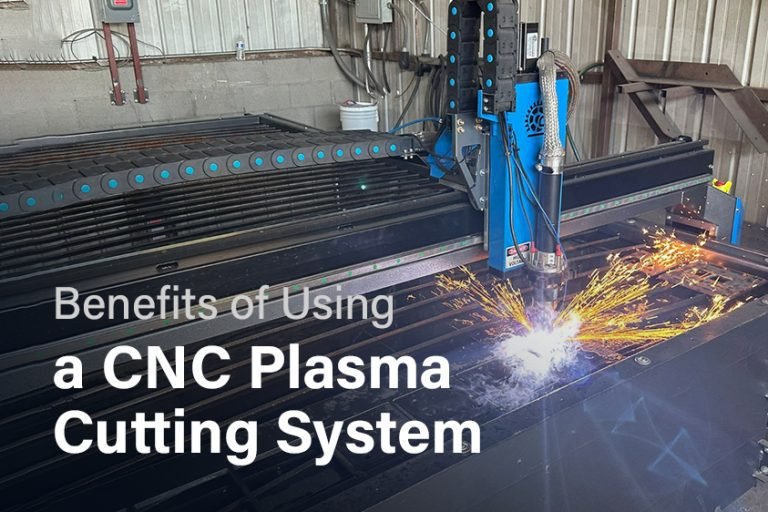

- CNC Plasma Cutters:

- Utilized for cutting metal sheets and plates using a high-velocity plasma jet.

- Applications: Metal fabrication, architectural and decorative metalwork, and industrial manufacturing.

- CNC Laser Cutting Machines:

- Employed to cut materials such as metal, plastic, and wood using a laser beam.

- Applications: Sheet metal cutting, engraving, signage, and intricate designs in various materials.

- CNC Router Machines:

- These are generally used for cutting, shaping, and engraving materials like wood, plastic, and composites.

- Some of its applications are Woodworking, cabinetry, sign-making, and artistic engraving.

Benefits of a CNC machine

|

Benefit |

Description |

|

Precision |

They are often regarded for their precision and accuracy, resulting in consistent and high-quality products. |

|

Automation |

This is one of the USPs of CNC machines, which offer automation which means they can operate continuously with minimal human intervention, increasing productivity and reducing labor costs. |

|

Flexibility |

They are easily reprogrammable for a variety of tasks, reducing the need for multiple machines and setups. |

|

Complex Shapes |

CNC machines can produce intricate and complex shapes that would be difficult or impossible to achieve manually. |

|

Consistency |

Products are highly consistent, reducing defects and ensuring uniformity in mass production. |

|

Efficiency |

Faster production cycles, reduced setup times, and minimal downtime contribute to improved efficiency. |

|

Reduced Waste |

Precision cuts and optimized toolpaths minimize material wastage, saving costs and reducing environmental impact. |

|

Operator Safety |

Operators have reduced exposure to dangerous tasks, improving workplace safety and reducing the risk of accidents. |

|

Cost Savings |

Over time, CNC machines can be cost-effective due to reduced labour, improved material usage, and increased production speed. |

|

Prototype Development |

They are useful for rapid prototyping, allowing designers to test and refine product designs more quickly. |

Why should beginners choose a CNC plasma cutting machine?

|

Aspect |

CNC Plasma Cutting Machine Advantages for Beginners |

|

Ease of Use |

User-friendly software interfaces make it accessible to beginners. |

|

Versatility |

Can cut a wide range of materials, including steel, aluminum, and more. |

|

Precision |

Offers high precision and repeatability in cutting, ideal for intricate designs. |

|

Speed |

Cuts materials quickly, reducing production time compared to manual methods. |

|

Cost-Effective |

Lower initial investment and operational costs compared to other cutting technologies. |

|

Minimal Setup Time |

Quick setup and minimal maintenance requirements make it suitable for beginners. |

|

Customization |

Easily adaptable for personal projects and can produce intricate, custom designs. |

|

Learning Resources |

Plenty of online tutorials and resources available for beginners to learn and improve skills. |

|

Safety |

Generally considered safer than some other cutting methods, with less risk to operators. |

|

Scalability |

Can be scaled up as skills and requirements grow, making it a long-term investment. |

What factors to consider when choosing a CNC plasma cutting machine for beginners?

|

Factor |

Consideration |

Description |

|

Machine Size |

Cutting Area |

Determine the maximum dimensions of materials the machine can handle. |

|

Cutting Capacity |

Thickness and Material |

Check the machine’s capability to cut through different materials and their thicknesses. |

|

Motion Control |

Ensure the machine comes with user-friendly and accessible CNC software for programming. |

|

|

Power Source |

Power Supply |

Ensure the machine’s power requirements match your workshop’s electrical capacity. |

|

Torch Height Control |

Automatic or Manual |

Decide between automatic torch height control for precise cuts or manual adjustments. |

|

Cutting Speed |

Inches per Minute (IPM) |

Consider the machine’s cutting speed, as it affects production efficiency. |

|

Accuracy and Precision |

Cutting Tolerance |

Look for the machine’s rated cutting tolerance and overall precision. |

|

Ease of Use |

User Interface |

Choose a machine with an intuitive and easy-to-use control panel or software interface. |

|

Portability |

Weight and Mobility |

Determine if you need a portable machine and check its weight for transportation. |

|

Price and Budget |

Cost and Financing |

Set a budget and explore financing options that fit your financial constraints. |

|

Consumables and Maintenance |

Replacement Parts and Service |

Consider the availability and cost of consumables, as well as machine maintenance requirements. |

|

Support and Training |

Manufacturer Support and Training |

Check for available support, warranties, and training resources from the manufacturer. |

|

Safety Features |

Safety Mechanisms |

Ensure the machine includes safety features like emergency stop buttons and fume extraction systems. |

Types of CNC plasma cutting machines

- Conventional Plasma Cutting Machines

- High-Definition Plasma Cutting Machines

- Robotic Plasma Cutting Systems

- Pipe and Tube Plasma Cutting Machines

- Multi-Process Plasma Cutting Machines

Features to look for in a CNC plasma cutting machine for beginners

When looking for a CNC plasma cutting machine for beginners, there are several key features and factors to consider. Here’s a table outlining the important features and considerations

|

Feature/Consideration |

Description |

|

Cutting Area |

The size of the work area the machine can handle. |

|

Cutting Thickness |

The maximum thickness of the material the machine can cut. |

|

CNC Controller |

User-friendly and easy-to-learn controller software. |

|

Torch Height Control |

Automatic or manual height adjustment for precise cuts. |

|

Plasma Power Source |

The power and amperage rating suitable for your materials. |

|

Material Compatibility |

Check if the machine can cut various types of metals. |

|

Price |

Consider your budget and cost of consumables. |

|

Software Compatibility |

Compatibility with CAD/CAM software for designing and cutting. |

|

Ease of Assembly |

Some machines may require assembly; consider your skill level. |

|

Portability |

Will you need to move the machine, and is it portable? |

|

Safety Features |

Features like emergency stop, fume extraction, and more. |

|

Warranty and Support |

Availability of warranty and customer support. |

|

Reviews and Recommendations |

Seek feedback from other beginners and experts in the field. |

Some of the Best CNC Machines for Beginners

-

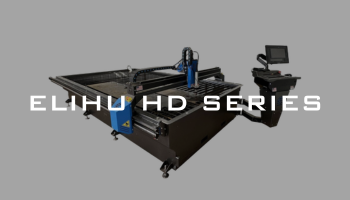

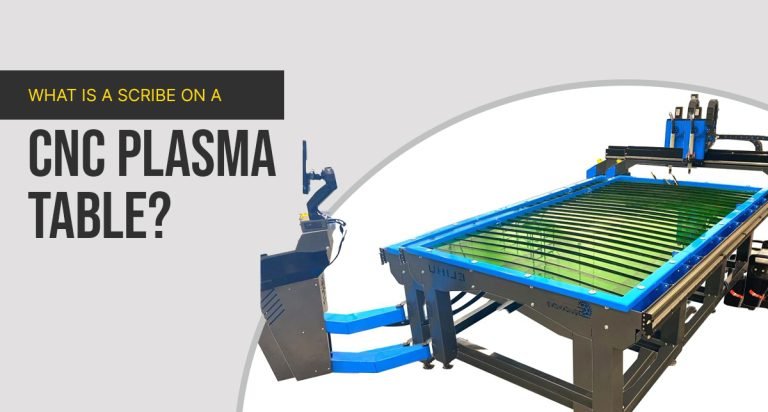

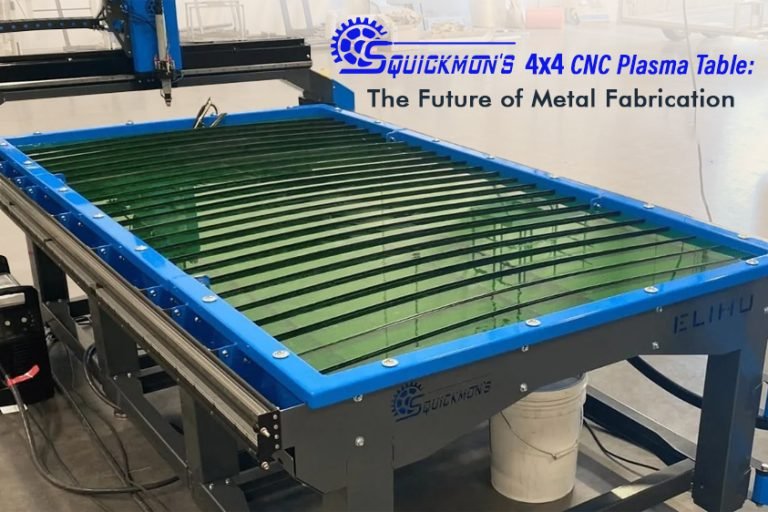

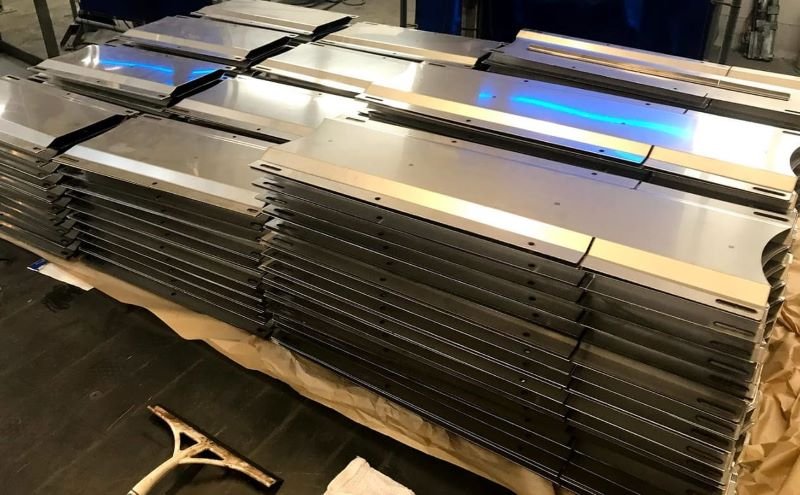

ELIHU HD SERIES PLASMA

Compatibility:

The Elihu HD Series CNC systems are configured to operate seamlessly with Hypertherm and Thermal Dynamics conventional plasma power supplies. If the need arises to upgrade to a larger plasma system, a straightforward process involves unplugging the current unit and connecting the new power supply to the compatible CPC port located on the back panel of the new unit.

True Turn Key Systems:

The Elihu HD Series system is shipped with a robust, fully welded steel frame measuring .1875” in thickness, and it arrives fully assembled. With electrical and air supply preparations made prior to the machine’s arrival, the entire system can be set up and ready for operation in less than 45 minutes. Onsite training is available for all customers in the United States but is not mandatory.

Engineered and Tested:

Squickmon designs, manufactures, and rigorously tests all machinery before release. You can trust that your system will operate at its full capabilities. Our team of software, electrical, and mechanical engineers collaborates to create and construct the finest system in the Lite Industrial market.

-

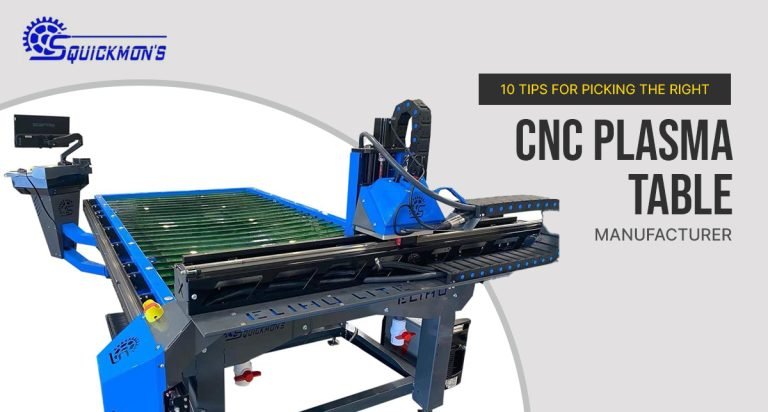

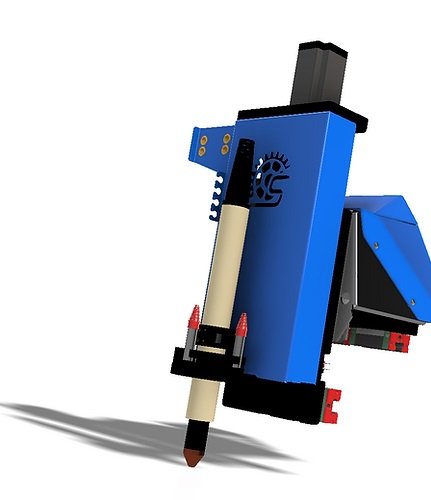

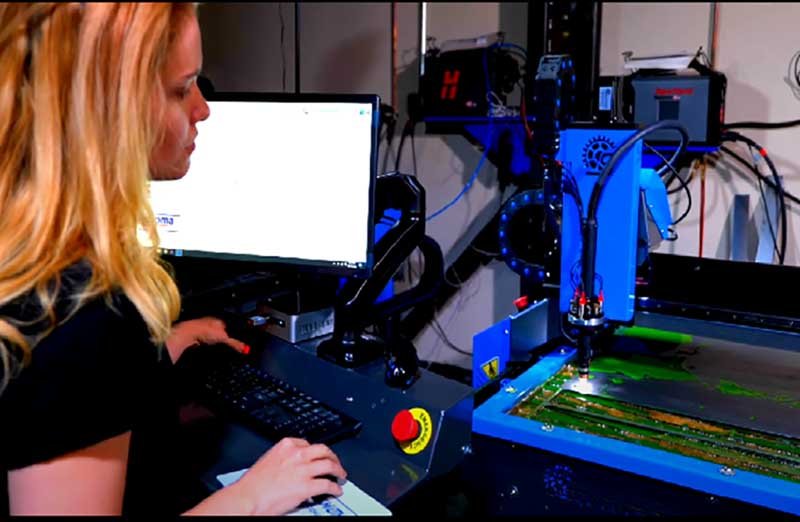

ELIHU LITE SERIES CNC PLASMA

The Elihu Lite Series CNC plasma system incorporates dynamic torch height control (DTHC), featuring a responsive feedback control that rapidly and accurately adjusts multiple times per second to maintain precise cutting height. This adjustment is achieved by monitoring voltage readings from the torch tip to the material. With advanced functionalities such as DTHC sampling and DTHC on/off control, operators can easily fine-tune cut height settings with just a few clicks within the software. Gone are the days of mid-cut arc voltage adjustments to uphold cutting height, as this fully integrated solution takes care of the task, enhancing cut quality and prolonging consumable life.

The newly introduced Z-axis assembly adopts a proven linear slide design composed of 9 roller bearings (4 adjustable, 5 fixed). This design, carefully chosen for its durability in harsh industrial environments, eliminates recirculating bearings near the cutting zone. The assembly includes an integrated ball screw drive, ensuring smooth and frictionless movement for the DTHC. Additionally, it allows for expansion capabilities, such as pneumatic etching, sharpie marker functions, oxy-fuel cutting, and other multi-process options, all configurable within a single universal design (requires upgraded software option).

Every machine in the series now features a collision detection head. This innovative torch holder design eliminates the need for a breakaway torch mount. Instead of physically dismounting the torch in case of an obstruction, the collision system automatically repositions itself to its exact location without operator intervention. This design employs proximity sensors that trigger if the torch body deviates within 2 degrees relative to its 90-degree cutting position. The holder design also includes standard 2-axis torch squaring, ensuring that the torch can be adjusted for perpendicularity to the cutting surface.

Conclusively, when selecting a CNC plasma cutting machine as a beginner, consider key factors like cutting area, thickness, software, safety, and price. The right choice will enhance your metal fabrication experience, so research and match the machine’s features to your specific needs and goals. With the right equipment and dedication, you can turn raw materials into artistic creations.

If you are a beginner and wondering “Where can I find plasma cutting near me?” you can get in touch over the call here at +18777865027 or visit the website https://squickmons.com