The Complete Guide to CNC Press Brake Machines: What You Need to Know

Introduction

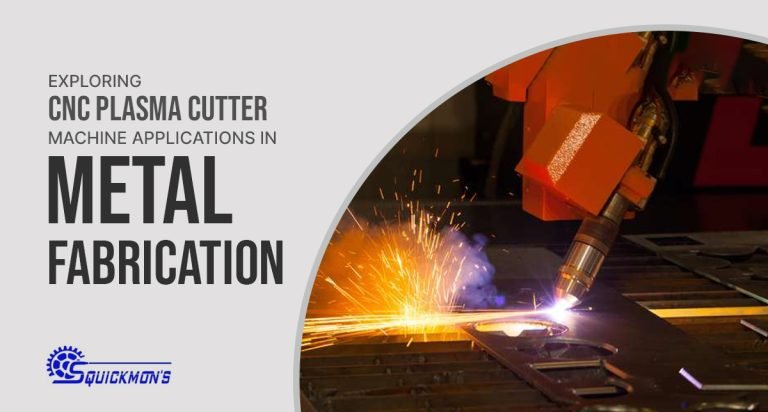

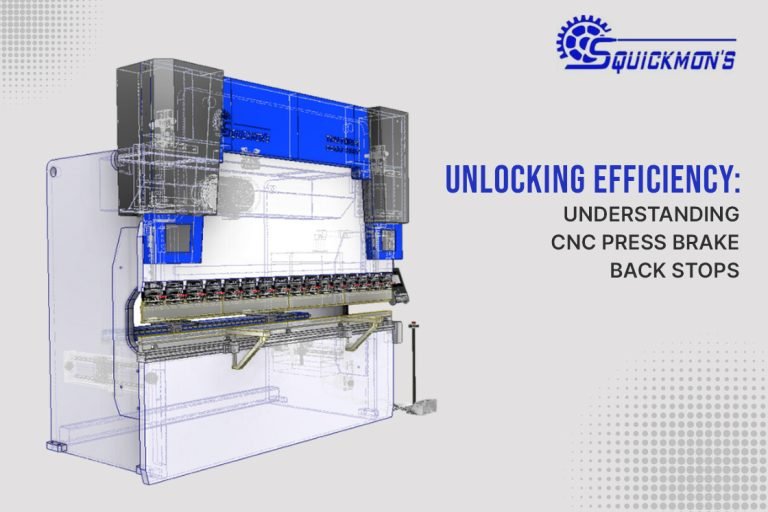

One of the important machines that are used for metal shaping is a CNC press brake machine; it allows accurate and effective bending of sheet metals. Computer-controlled (CNC) press brakes have replaced manual operations over time as press brakes today, speeding both the manufacturing operations and accuracy. Of modern production, CNC brake press technologies are requisite to form high-quality metal components used in different sectors.

You will find in this tutorial all about the CNC press brake machine definition, types, components, uses, advantages, and important factors in buying it.

Being Aware of CNC Press Brake Equipment

What is a CNC press brake machine?

A computer numerical control (CNC) system uses a CNC hydraulic press brake machine, a metal bending tool, to automate and improve sheet metal forming precision. CNC models are the preferred option in contemporary metalworking because they provide higher accuracy, efficiency, and repeatability than manual press brakes.

Components of a CNC Press Brake

- Frame – Provides structural stability.

- Ram – Moves up and down to apply force.

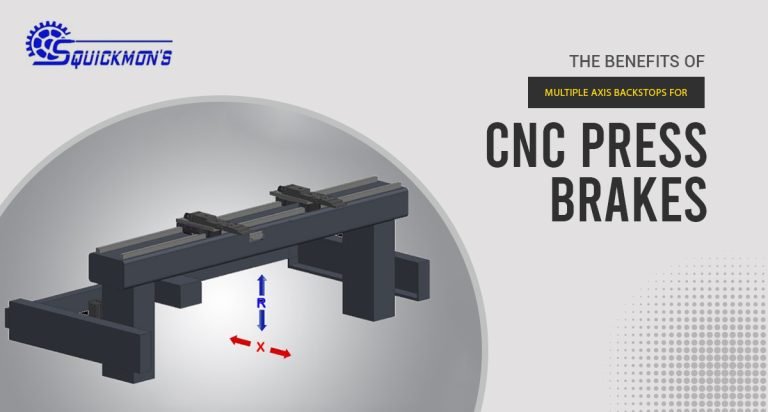

- Back Gauge – Ensures precise positioning of metal sheets.

- Control System – CNC software that programs bending operations.

- Tooling – Punches and dies that define bending shapes.

Working Principle of a CNC Press Brake

- The operator inputs the bending parameters using CNC software.

- The CNC system calculates the required force and movement.

- The press brake applies pressure to bend the metal accurately.

- The final product is checked for precision, ensuring minimal errors.

Types of CNC Press Brake Machines

- Hydraulic CNC Press Brakes – In heavy-duty applications such as automotive and aerospace, hydraulic press brakes are fitting machines and probably best.

- Electric CNC Press Brake – Fully electric types will save energy, are accurate, and allow speed; these are what one would want for high-precision applications, such as the electronics industry.

- Hybrid CNC Press Brake – The hybrid concoction of hydraulic and electric technology shares the best- energy efficiency and powerful bending capabilities.

- Manual and CNC Press Brakes – Manual press brakes are still used for small volume production and custom fabrication. However, CNC press brakes dominate the high volume production arena due to speed, consistency, and automation.

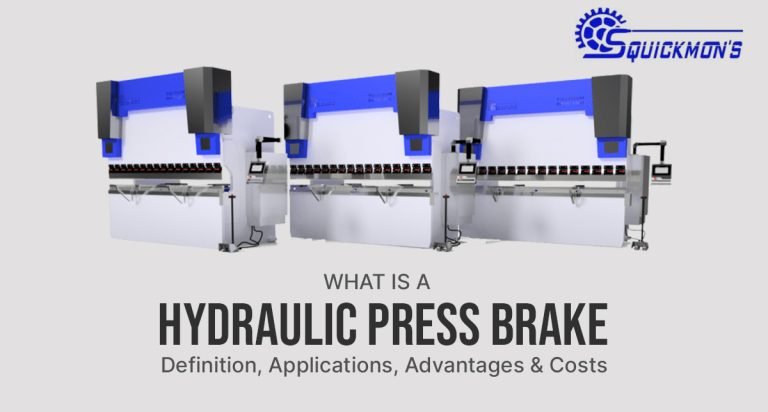

Read also: What is a Hydraulic Press Brake? Applications, Advantages & Costs

Applications of CNC Press Brake Machines

Industries Using CNC Press Brakes

- Automotive – Bending chassis components and body panels.

- Aerospace – Fabricating precision aircraft parts.

- Construction – Producing structural steel components.

- Electronics – Creating metal enclosures for devices.

Common Metal Products Made with CNC Press Brakes

- Brackets, panels, and cabinets

- Custom industrial machine components

- Decorative metal fabrication

Advantages of CNC Press Brake Machines

- Precision and Accuracy – A CNC press brake machine ensures exact bending angles, reducing errors and material waste.

- Efficiency and Productivity – Higher programmable and faster processing speeds generally optimize production and reduce operator costs.

- Cost-Effectiveness – Using CNC brake press saves on material wastage and rework work, thereby enhancing profitability.

- Flexibility and Customization – CNC systems allow fast programming for a wide variety of bending operations, providing good ability for product customization.

The operator safety and ease of use of modern CNC hydraulic press brake machines are assured with various new safety features, including emergency stop buttons, light curtains, and intelligent sensors.

Major Considerations in the Purchase of a CNC Press Brake

Machine Specifications

- Tonnage capacity – Determines the force required for bending.

- Bending length – Defines the maximum width of metal sheets that can be processed.

Control System and Software

- User-friendly programming for simple operation.

- Compatibility with CAD/CAM software for seamless integration.

Material and Thickness Handling

- Different metals require specific bending pressures and tooling.

- Ensuring the machine supports your material needs is crucial.

Tooling Options

- Standard and custom punches and dies for various applications.

- Quick-change tooling systems for better efficiency.

Energy Conservation and Environmental Sustainability

- Hydraulic, electric, or hybrid-type-the right choice in respect of energy-efficiency and operation cost.

Read also: What Is The Best Press Brake For Metal Fabrication?

Maintenance and Troubleshooting for CNC Press Brakes

Routine Maintenance Checklist

- Regular lubrication and cleaning to prevent wear.

- Checking hydraulic oil levels and filters for smooth operation.

- Updating CNC software and calibration for accuracy.

Common CNC Press Brake Issues and Solutions

- Incorrect bending angles – Requires recalibration.

- Software errors – Troubleshoot by checking CNC settings.

- Hydraulic issues – Inspect oil levels and pressure systems.

Safety Best Practices

- Operator training to prevent accidents.

- Emergency stop functions and protective barriers for workplace safety.

Future Trends in CNC Press Brake Technology

Automation and Industry 4.0 Integration

- IoT-enabled CNC press brake machines for smart manufacturing.

- AI-driven optimization for reducing waste and improving accuracy.

Advanced Materials and Bending Techniques

- New high-strength alloys require improved CNC bending methods.

- Multi-axis bending for complex shapes and precision forming.

Sustainable and Energy-Efficient Machines

- Eco-friendly press brakes reduce power consumption.

- Electric CNC press brake machines eliminate hydraulic fluid waste.

Conclusion

The Best CNC press brake transforms the process of forming metal, bringing accuracy, unparalleled efficiency, and incredible savings into any facility. Whatever field might have to do with automotive, aerospace, construction, or electronics, the intelligent investing in the correct CNC press brake will augment productivity and wear down operational cost.

If you’re thinking of buying one, watch out for required tonnage, controls, material handling, and energy consumption. Also, you should browse for some trusted names to get your machine.

CNC press brakes have become more intelligent, faster, and greener due to the advent of modern technology, making metal fabrication probably the most efficient and cost-effective practice today.