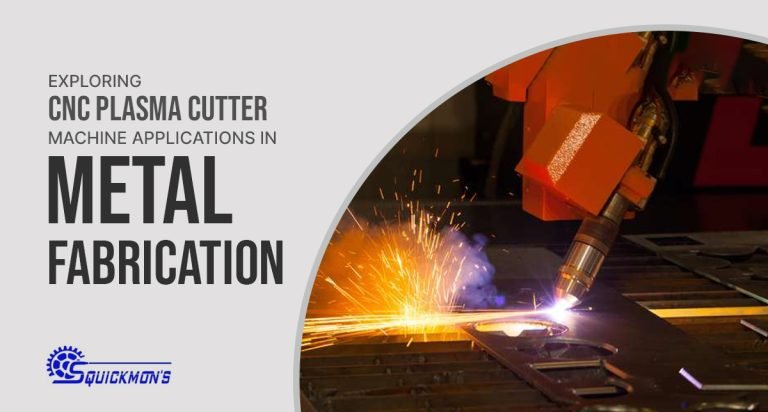

Benefits of Using a CNC Plasma Cutting System

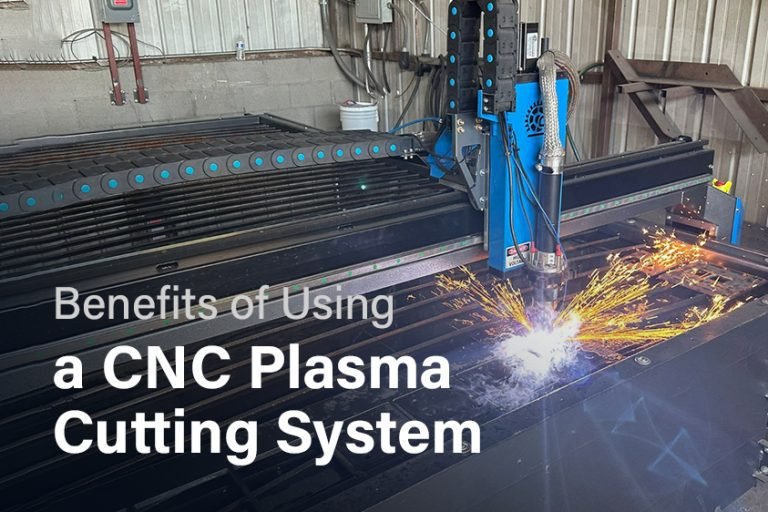

In contemporary manufacturing and metal fabrication, CNC plasma cutting machines stand out as essential instruments, transforming the approach to shaping and moulding metal in businesses. We will learn more about the benefits of Using a CNC Plasma Cutting System.

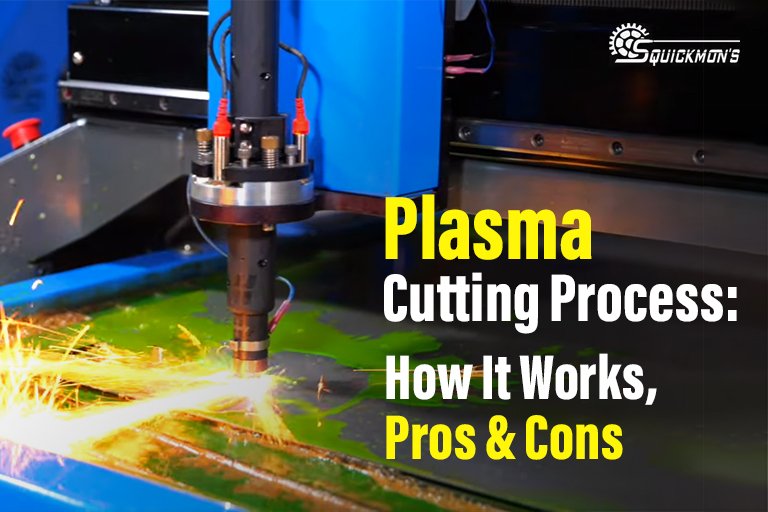

What is CNC Plasma Cutting?

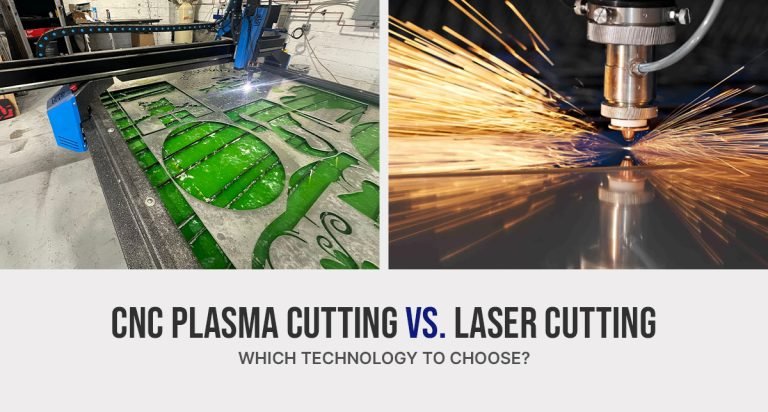

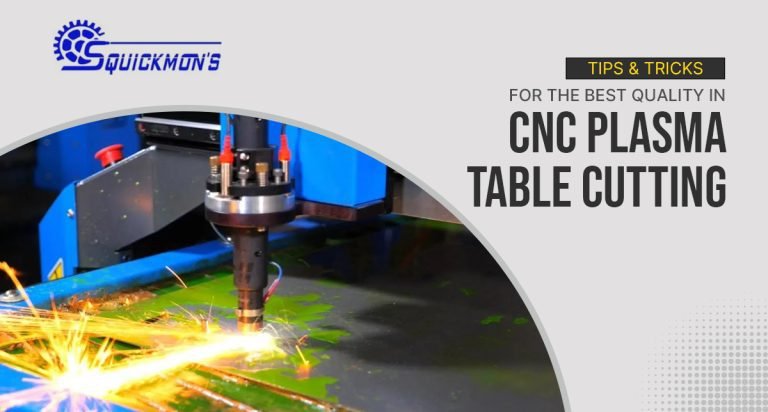

CNC plasma cutting machines are a technological marvel in the field of metal fabrication. This system uses a plasma beam to cut through metals. What sets CNC plasma cutters apart is their integration with computer numerical control, allowing for precise and automated control of the cutting process.

The CNC component of these machines refers to the computerized system that guides the plasma cutter along a programmed path, ensuring accuracy and repeatability in the cutting process. The CNC plasma cutting machine interprets digital design files, often in the form of CAD (Computer-Aided Design) drawings, and translates them into precise movements and instructions for the cutter.

Top 7 Benefits of Using a CNC Plasma Cutting System

-

Precision and Accuracy

One of the primary advantages of CNC plasma cutting machines is their unparalleled precision. The computerized control ensures that the cutter follows the programmed path with microscopic accuracy, resulting in clean and intricate cuts.

-

Versatility

From thin sheets to thick plates, these machines adapt to the specific requirements of the job. Their ability to cut various metals makes them an ideal choice for businesses dealing with diverse materials in their operations.

-

Speed and Efficiency

Speed is a key factor in any manufacturing process, and CNC plasma cutting systems excel in this aspect. The automated nature of these machines allows for rapid cutting without compromising precision. This efficiency not only increases productivity but also reduces lead times for projects, enabling businesses to meet tight deadlines.

-

Cost-Effectiveness

Despite their advanced technology, CNC plasma cutters offer cost-effective solutions for metal fabrication. The automation streamlines the production process, minimizing labour costs and material wastage. Additionally, the precision of the cuts reduces the need for secondary processes, further optimizing costs for businesses.

-

Complex Shape Cutting

Traditional cutting methods may struggle with intricate designs and complex shapes, but CNC plasma cutting machines excel in this regard. The precision and flexibility of these systems enable the creation of detailed and intricate cuts that would be challenging or impossible to achieve using conventional methods.

-

Minimal Material Waste

The automated nature of CNC plasma cutting ensures that cuts are made with maximum efficiency, minimizing material wastage. This not only contributes to cost savings but also aligns with the growing emphasis on sustainable and eco-friendly manufacturing practices.

-

User-Friendly Operation

While the technology behind CNC plasma cutting systems is sophisticated, the operation of these machines is designed to be user-friendly. With intuitive software interfaces, operators can easily program the cutter, load design files, and monitor the cutting process. This reduces the learning curve for operators and enhances overall efficiency in the workplace.

Also check out Is a CNC Plasma Table Worth It?

Where Can I Buy CNC Plasma Cutting Machines for My Business?

Acquiring a CNC plasma cutting machine for your business involves careful consideration of your specific needs and preferences. Several reputable manufacturers and suppliers offer a range of CNC plasma cutters with varying features and capabilities. Some well-known brands in the industry include Squickmons, Hypertherm, ESAB, and Lincoln Electric.

When looking to purchase a CNC plasma cutting machine, it’s essential to assess factors such as cutting capacity, speed, software capabilities, and after-sales support. Consideration of these aspects will help ensure that the machine aligns with your business requirements and provides a solid return on investment.

In addition to directly approaching manufacturers, businesses can explore reputable distributors and authorized dealers that specialize in CNC plasma cutting systems. These distributors often provide comprehensive support, including installation, training, and maintenance services.

Some of the Best Products by Squickmons Are As Below

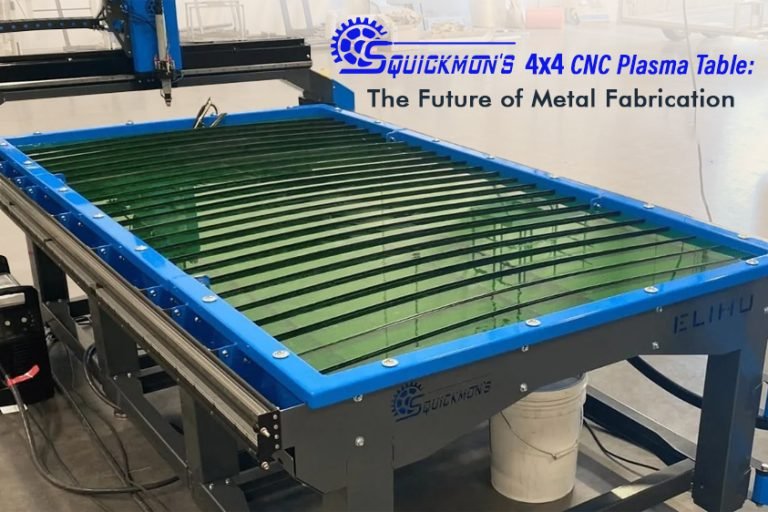

- Elihu S Series: Precision and Reliability

The Elihu S Series represents a pinnacle of plasma cutting technology, offering a perfect blend of precision and reliability. Boasting a solid construction with a 1-year warranty, this series features a 3” deep water pan and a welded-in slat grid, ensuring durability and stability during operation. For enhanced functionality, users can opt for a Spring-loaded Collision Detection head with self-centering and an additional leveling system. With a focus on efficiency and performance, the Elihu S Series is designed to meet the needs of hobbyists and fabricators that demand high-quality plasma cutting.

- Elihu Lite Series: Efficiency and Versatility

The Elihu Lite Series is a cutting-edge solution designed for efficiency and versatility in plasma cutting applications. Backed by an impressive 5-year warranty, this series offers material loading assistance, a 6” deep water pan, and a 4” Z-Axis travel for intricate cutting requirements. The 8-leg design with leveling feet ensures stability, and the removable slat grid facilitates easy fixturing. Featuring a Spring-loaded Collision Detection head with self-centering and an optional leveling system, the Elihu Lite Series is ideal for users seeking a reliable and adaptable plasma cutting solution.

- Elihu HD Series: Robust Powerhouse for Heavy-Duty Applications

Engineered for heavy-duty applications, the Elihu HD Series stands as a robust powerhouse in the realm of plasma cutting technology. With a 5-year warranty, material loading assistance, and a 6” deep water pan, this series offers unmatched performance. The extended Z-axis travel, raised gantry with 6.5” clearance, and a colossal 15,000lb loading capacity make it perfect for tackling large and demanding projects. The HD Series boasts advanced features like a removable slat grid for fixturing, optional integrated bladder system, and helical rack and pinion gearing, making it the ultimate choice for industries requiring precision and power.

Common Features Across All Series: Cutting-Edge Technology at Your Fingertips

All Elihu plasma cutting systems come equipped with cutting-edge features to streamline your workflow. Standard inclusions are motor reduction systems, basic CAD, basic CAM, and basic CNC, ensuring a comprehensive package for your cutting needs. Users have the option to upgrade to the Arc Professional software package for advanced capabilities. The XLR connection on motor cabling with shielding, shielded Ethernet connection for signal transfer, and confined wiring sub-assemblies make diagnostics and troubleshooting easy. With optional extended gantry for large part processing, Elihu plasma cutting systems are designed to evolve with your growing needs.

In conclusion, CNC plasma cutting systems epitomize efficiency and precision in modern metal fabrication, offering businesses a transformative solution for intricate, cost-effective, and rapid cutting processes. Investing in these cutting-edge tools positions industries at the forefront of innovation in the dynamic landscape of contemporary manufacturing.

If you are a beginner and wondering “Where can I find plasma cutting near me?” you can get in touch over the call here at +18777865027 or visit the website https://squickmons.com/