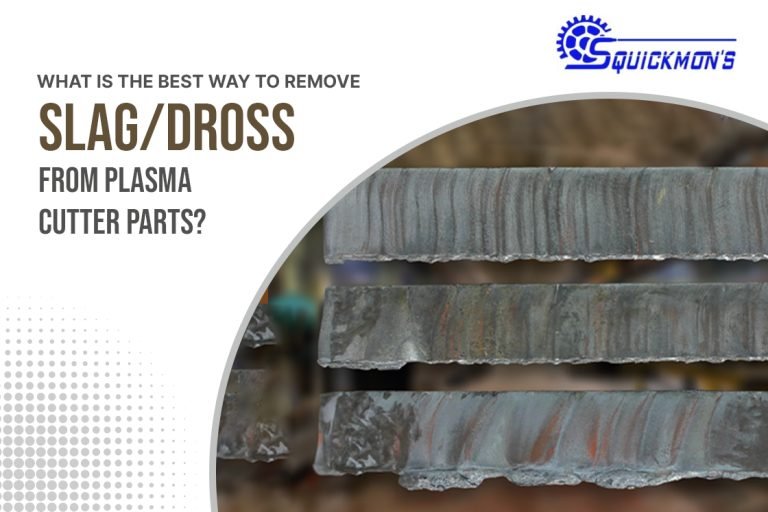

Best Tools for Removing Slag/Dross from CNC Plasma Cut Parts

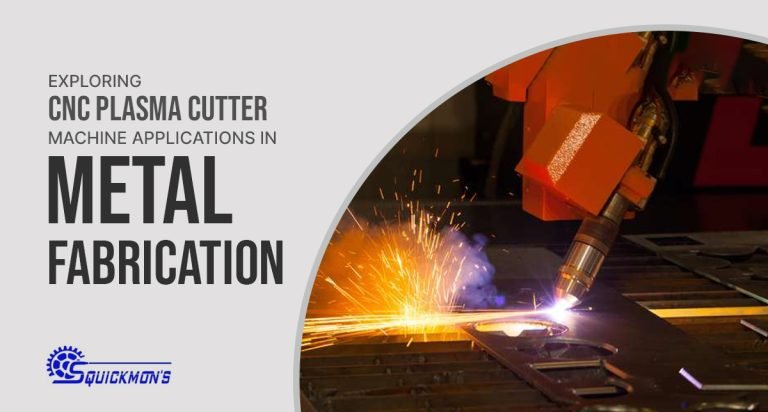

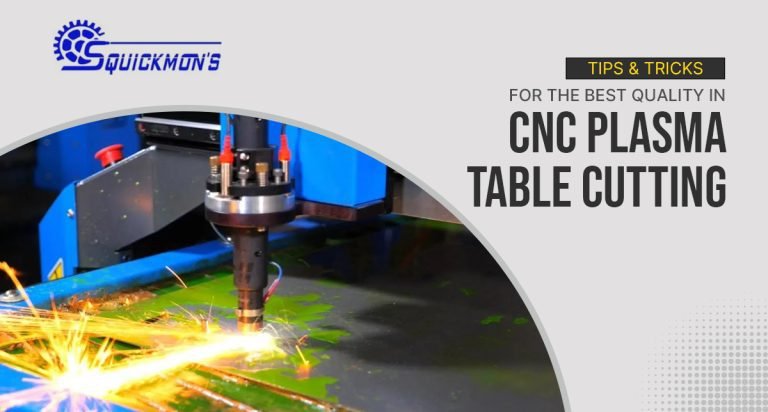

CNC plasma cutting is an awesome way to shape metal parts just right. However, sometimes the unwanted remnants called slag and dross pop up on the edges. No worries! In this handy guide, we’ve got your back on banishing them for good. Whether you’re a metal moulding master or just starting out, get ready for some awesome tips to make your work shine bright!

What is The Best Way to Remove Slag and Dross from Plasma Cutter Parts?

Handheld Tools for Slag and Dross Removal:

Handheld tools are like superheroes in the cleanup process after cutting metal. They’re flexible and super precise, perfect for getting rid of slag and dross from plasma cuts from a CNC plasma cutting machine. From chipping hammers to nifty wire brushes, there’s a tool for every job and metal type. Let’s dive into some of the best handheld tools and why they’re extremely helpful!

- Chipping Hammer: Imagine a chipping hammer as your trusty sidekick in the battle against slag and dross on metal surfaces. With its sharp, pointed end, it’s like a precision chisel, while the flat end is perfect for wider scraping. When picking one, think about its weight, handle grip, and toughness to make sure it’s your hero in cleanup!

- Wire Brush: Think of wire brushes as your go-to superheroes for cleaning up cut parts of plasma from CNC plasma cutting. They come in all sizes and bristle materials, like tough steel or gentle brass, to zap away surface debris without harming the metal underneath. For maximum performance, go for one with strong bristles and a comfy grip for long-lasting action!

- Grinding Wheel: When slag and dross dig in their heels, it’s time to unleash the heavy artillery: the grinding wheel! With an angle grinder and abrasive disc by your side, you’ll tackle those stubborn spots like a seasoned pro, leaving them no chance to stick around. Just grind away and see those stubborn bits vanish, leaving your edges smooth as butter! But remember, go easy to avoid overheating or messing up the surface!

- Pneumatic Chisel: When it’s time for heavy-duty cleanup on big fabrication projects, pneumatic chisels are the way to go! These air-powered tools are a pack a punch, zapping away tough slag and dross in a flash. Just use one and watch as it makes quick work of even the most stubborn buildup. But remember, safety first!

Automated Systems for Slag and Dross Removal:

When it comes to tackling slag and dross on CNC plasma cut parts, let’s think outside the toolbox! Enter automated systems, the superheroes of cleanup. With robotic arms and CNC magic up their sleeves, they zoom in to rescue the day, effortlessly cleaning up without breaking a sweat. Now, let’s dive into the action and see these futuristic wonders in motion:

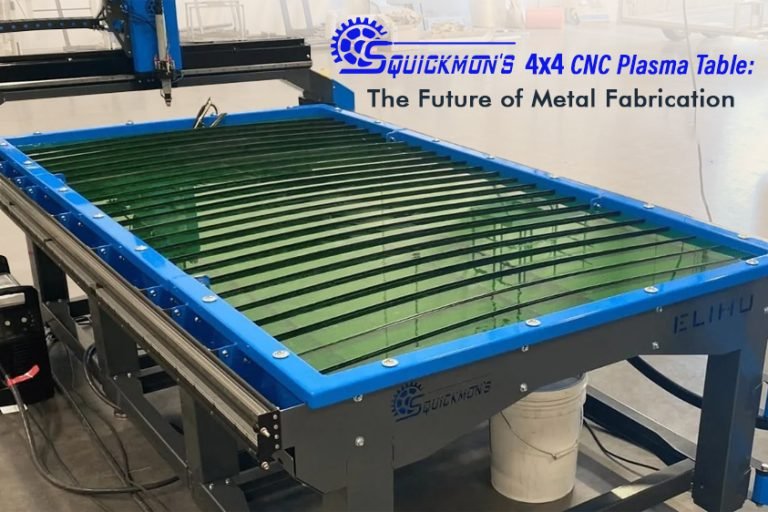

- Slag Removal Tables: Slag removal tables are specialized workstations designed to automate the cleanup process for CNC plasma cut parts. Equipped with conveyor systems and adjustable slag trays, these tables facilitate the efficient removal and collection of slag and dross residues. By integrating seamlessly with CNC plasma cutting machines, slag removal tables enable continuous production without the need for manual intervention.

- Robotic Deburring Systems: Picture a squad of robotic heroes equipped with deburring tools, swiftly removing slag and dross from metal parts with precision and speed. These robotic deburring systems guarantee flawless control, ensuring each piece shines. With smart programming and flexible tooling, they’re the go-to for tackling any cutting challenge, no matter the material or task.

- CNC Plasma Cutting Machines with Integrated Slag Removal: Picture this: CNC plasma cutting machines with their own built-in cleanup crew. These machines come fully equipped with integrated slag trays, powerful suction systems, and automated cleaning routines, making the switch from cutting to cleanup a breeze. Say goodbye to external slag removal gear—these integrated solutions keep the fabrication process flowing smoothly, with minimal downtime.

- Water Jet Slag Removal Systems: Enter the world of water jet slag removal systems—a revolutionary approach to cleanup. Using high-pressure water jets, they wash away slag and dross from CNC plasma cut parts with gentle precision. Perfect for delicate materials and complex shapes, this eco-friendly method ensures pristine cuts without any risk of thermal damage or surface distortion. Seamlessly integrated into existing workflows, it’s the ultimate solution for flawless results every time.

Integration of Tools with CNC Plasma Cutting Workflow:

To make slag and dross removal a breeze, it’s all about seamlessly blending tools into your CNC plasma cutting machine routine. By picking the right tools, tweaking operating settings, and nailing post-cutting steps, you can slash downtime and boost productivity. Here are some top tips for getting it right:

- Pre-Cut Preparation: Before embarking on your CNC plasma cutting machine journey, ensure you have all the necessary equipment for slag and dross cleanup within easy reach. This includes having your handheld tools, automated systems, and personal protective gear prepared and ready for immediate use. Proper prep ensures a smooth cleanup process and keeps production running without a hitch.

- Tool Selection: Customize your cleanup arsenal to match the material, thickness, and cutting style of your CNC plasma process. Take into account the material’s strength, texture, and desired finish when selecting between handheld tools or automated systems for slag and dross cleanup. Explore various tool options creatively to discover the most effective and budget-friendly solution for your workflow.

- Post-Cutting Inspection: Once the work of CNC plasma cutting machine is done, carefully inspect the cut parts for any slag and dross buildup. Utilize handheld tools or automated systems to eliminate any excess material, ensuring smooth and consistent edges. Make sure to thoroughly examine critical dimensions, surface quality, and overall appearance to fulfill quality standards and meet customer specifications.

- Routine Maintenance: Taking care of your tools & equipment is really important to keep them in great shape and lasting a long time. Make sure your handheld tools are clean and oiled to stop rust and keep them working smoothly. Give your automated systems a check for any damage, and replace any worn-out parts to avoid big repairs or stopping work unexpectedly. By looking after your tools regularly when you’re using a CNC plasma cutting machine, you’ll help them last longer and keep everything running smoothly.

Tips for Maximizing Efficiency in Slag and Dross Removal:

Achieving optimal efficiency in slag and dross removal requires careful planning, execution, and continuous improvement. Here are some tips to help fabricators maximize productivity and quality in the cleanup process:

- Optimize Cutting Parameters: Tweak those CNC plasma cutting machine settings, like speed, feed rate, and torch height, to keep slag and dross at bay. Dial in those parameters depending on the material, thickness, and the kind of clean edges you’re after. With the right adjustments, you’ll breeze through cuts, leaving behind minimal mess to tidy up.

- Implement Multi-Stage Cleanup: Break down the slag and dross removal process into multiple stages, each targeting specific areas of buildup or contamination. Start with coarse removal methods, such as chipping hammers or grinding wheels, to eliminate bulk residues, then proceed to finer deburring tools for surface refinement. By adopting a multi-stage cleanup approach, you can achieve smoother edges and reduce overall cleanup time.

- Utilize Software Solutions: Take advantage of software solutions and CNC programming tools to optimize tool paths and minimize slag and dross generation during cutting. Advanced nesting algorithms, lead-in/lead-out strategies, and corner smoothing functions can help reduce material waste and improve cut quality, resulting in less post-cutting cleanup required.

- Invest in Training and Education: Empower your operators and technicians with training and learning opportunities to ace the CNC plasma cutting table game. Arm them with the know-how to handle tools and gear safely and effectively, and keep them hungry for knowledge and growth to stay ahead of the curve on slag and dross removal techniques.

Conclusion

Cleaning up slag and dross from CNC plasma cuts is just like tidying your room—it’s essential for getting great results and keeping things running smoothly. By mixing and matching handheld tools, automated systems, and clever workflows, you’ll zip through cleanup and nail those high-quality finishes every time. Whether you’re slicing through mild steel, stainless steel, or aluminium, the tips and tricks in this guide will help you fine-tune your CNC plasma cutting game and wow your customers with flawless finished products.