How To Load Sheet Metal On Cnc Burn Table Properly

Burn tables are excellent tools for cutting sheet metal. However, loading large sheets onto your table can present a challenge. Thick sheets are weighty and thinner sheets may flex during the loading process, making both cumbersome.

Looking for guidance on how to load a steel plate/sheet on a CNC burn table? Well then, you’re in the right place because this is what this post will cover today. We will start with an overview of burn tables, then explain the right way to load higher gauge steep on it.

What is a burn table?

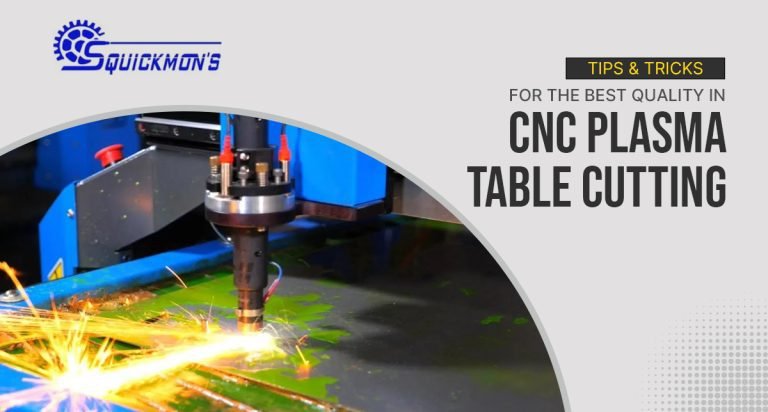

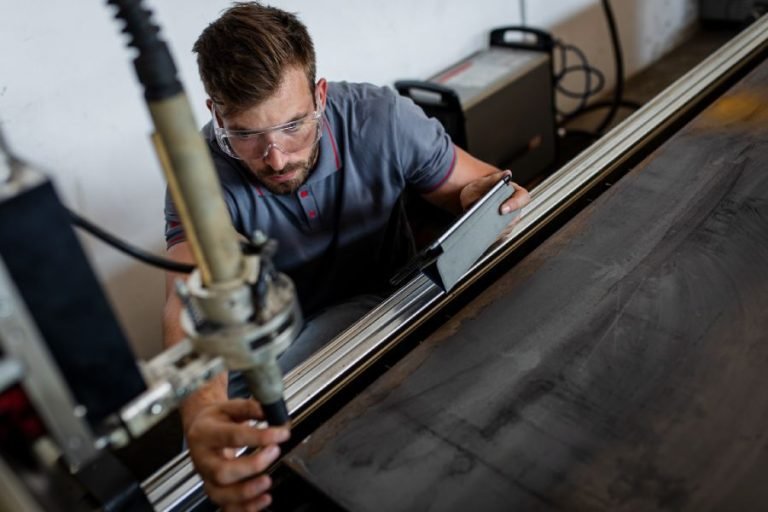

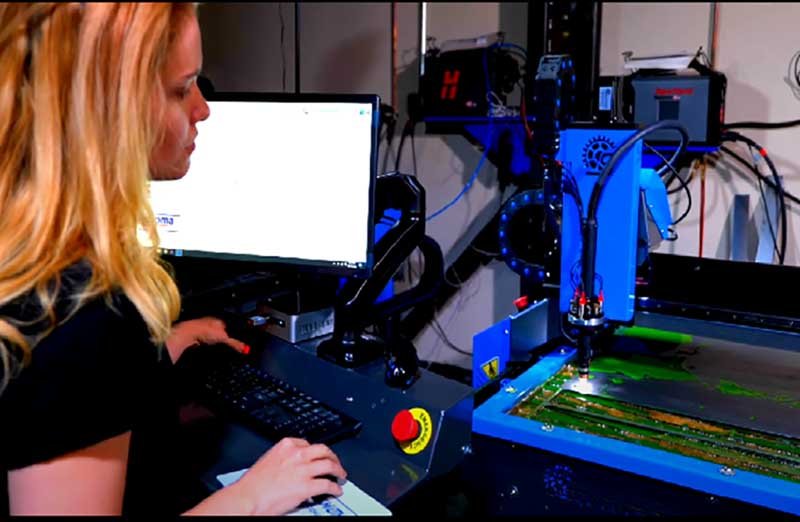

A burn table (aka. cutting table) has long been used as a term for a plasma cutting machine. Another name for it is CNC controlled plasma cutting table. The plasma-cutting process uses an arc or flame to slice through steel or “burn” the material, giving rise to the term “burn table.” CNC burn tables are typically used in conjunction with CNC cutting machines to cut through metal using plasma.

What is the function of a burn table?

A burn table facilitates the cutting of hot and cold rolled steel. Burning or thermal machines (cutting/burn tables) is the oldest way to perform metal shape cutting (falling just short of the conventional sawing and hammering techniques. Fabricators can also use them to create intricate designs and patterns on metal surfaces, making burn tables a versatile option for various metalworking applications.

What is the best way to load steel sheets on a burn table?

You can choose from various steel plate lifting equipment to load steel sheets on a burn table. Some options are:

- Industrial Lifting Magnets – These work best for heavy gauge sheets.

- Metal Plate Filters – Floor managers use these for small metal sheets.

Other handy accessories are plate clamps and slings, hooks, strips, and vacuum cups…

But regardless of the steel lifting device you’re using, it can be daunting to load metal sheets—especially thinner ones—onto the cutting table. The thinner sheets tend to flex more, making them challenging to load.

Moreover, lifting metal sheets with traditional devices such as clamps or strips can be a source of worry due to the risk of sudden drops and potential injuries or damages. Also, these methods can lead to sheet deflection.

Ever heard of magnetic lifting?

Magnetic lifting equipment offers a safer alternative, with small magnet lifters being particularly useful for small steel plates. These devices are simple and efficient, and they minimize the risk of accidents.

Ideally, you want a machine that consists of a magnetic lifting beam. Look for one that features multiple magnetic filters, as they simplify the process of picking up and moving steel sheets on the machine.

You might also be able to use the same equipment to unload both the cut pieces and remaining scraps from the table in a single motion. But this requires customization on the manufacturer’s end, so you’ll need to check whether it’s an option available with your supplier.

Once you have purchased magnetic lifting equipment, you also get to eliminate the chains and grabs during the loading and unloading process. Plus, the equipment creates a safer work environment by reducing the need for manual handling of multiple parts and eliminating the need for operators to climb on the burn table. This system can have a positive and significant impact on a company’s productivity by reducing labor and table downtime.

Related Posts: Are CNC Burn Tables a Good or Bad Idea?

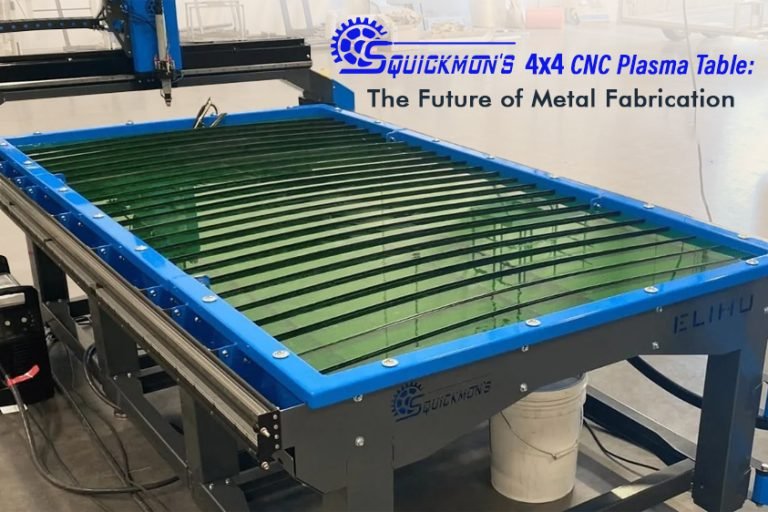

Is the burn table also important?

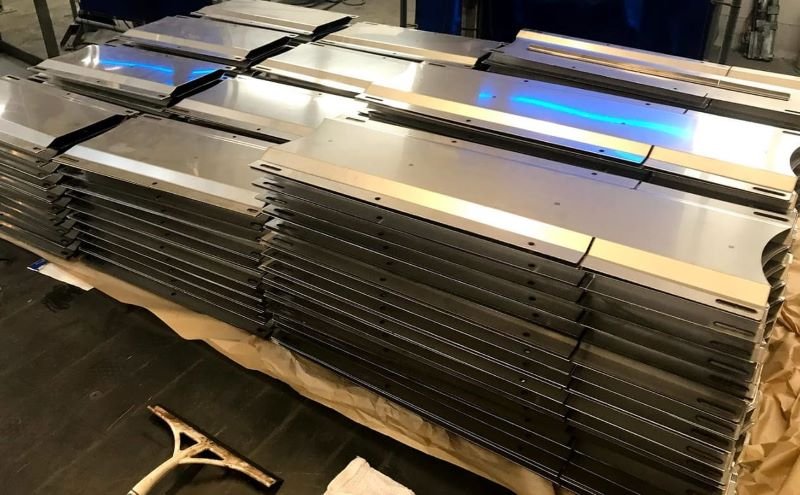

Certainly. If you attempt to load a heavy gauge steel sheet on a low-quality burn table, the table is likely to break down. Plus, the wrong type of table will struggle to add efficiency to the process. For loading steel sheets, it’s a good idea to choose a water burn table. These tables dissipate heat and keep steel sheets cool. Operators can use these tables without a dust collector to eliminate dangerous arch lights.

It’s also important to go with a trusted brand when it comes to burning tables. Squickmon’s offers CNC burn tables from Hypertherm and Victor Thermal Dynamics, which are designed to support leading plasma cutter brands. You can use these burn tables with both Powermax (including three-phase options) and Cusmaster machines to make your desired part. Plus, you can be sure that you’re investing in a high-quality table—all burn tables in our catalog are made in the USA and come with a 5-year manufacturer’s warranty.