Mechanized Plasma Cutting For The Hvac Industry

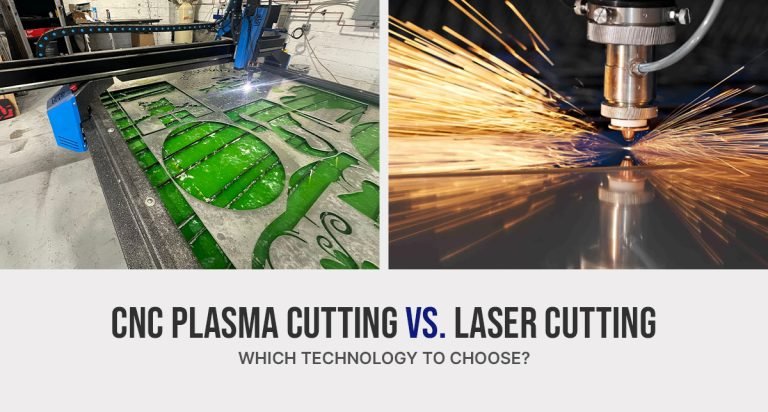

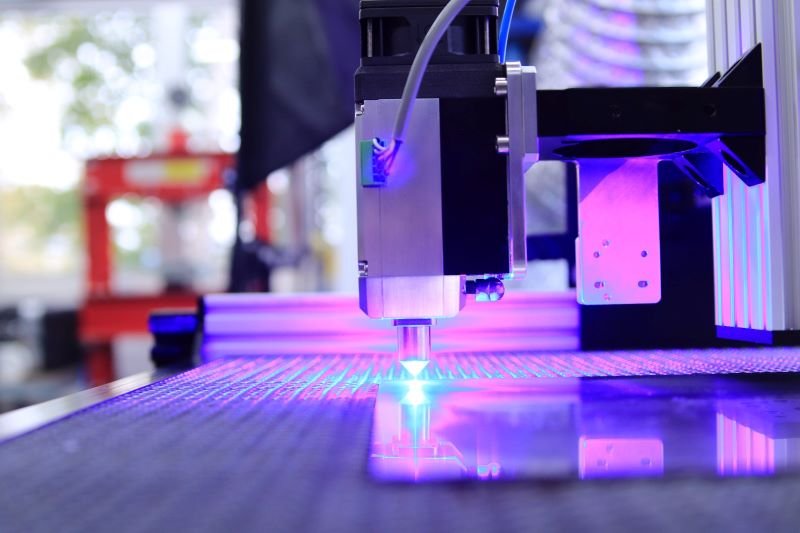

Plasma cutting has quickly become a standard for material fabrication in various industries. This fast, neat, and affordable cutting method is ideal for accurate, reliable cuts in light-metal projects. Moreover, plasma cutters easily transition from handheld to mechanized, thanks to the tool’s design.

One industry that has highly benefited from mechanized plasma cutting is heating, ventilation, and air conditioning (HVAC). Below, we’ll discuss how plasma cutters are used in this industry today and what potential improvements they make.

History of HVAC Plasma Cutting

Plasma cutting tools were first introduced to HVAC production in the 1980s when they were still basic in design. They consisted of a single-gas torch powered by a low-amp battery and were capable of cutting:

- 24-gauge galvanized steel

- ¼-inch mild steel

- ¼-inch stainless steel

- ¼ aluminum

They could achieve these results while maintaining a cutting speed of several inches per minute with minimal material loss. The low-amp plasma cutter setup was far less expensive than the high-amp alternatives, as it consumed less power without expensive bottle gases.

All of these features allowed for enormous strides in the production of HVAC equipment. Ductwork machining could be fully automated with a plasma cutter CNC machine that would output approximately 400 new frames per year, which led to a multifold increase in overall productivity

Due to the efficiency of plasma cutting in the HVAC sector, little has changed over the last few years. The main advancements have come in the components that make up a production operation. Essentially, plasma-cutting HVAC components have become faster and more affordable over time.

The Basic Setup for HVAC Plasma Cutting

An HVAC-focused plasma cutting machine consists of six components:

1. Computer Numerical Control (CNC)

Necessary for any computer-aided production machine, the CNC acts as the brain that controls the plasma machine as a whole. An operator enters the command for making the specific HVAC component directly into the machine or through a CAD-running computer. The machine interprets these commands and produces the desired component.

CNC can aid an HVAC designer with ductwork drawings based on the schematics of relevant buildings. The 3D schematics are translated into 2D production drawings that the machine reads. Each piece is labeled according to these designs, making it simple for them to be assembled when delivered.

2. A Gantry-style Cutting Machine

In earlier days, belt and cable drive machines were used to make HVAC components due to their lower costs. However, the resultant components weren’t the most reliable. Now, dual-drive rack-and-pinion cutting machines are used in manufacturing. Their more rigid design helps maintain accuracy and position control even while the machine runs at higher speeds, creating more uniform products.

3. A Plasma Arc Cutting (PAC) torch

The torch itself is where the machine gains its cutting power. These all consist of an electrode, a gas distributor, a nozzle, and a shield. The electrode provides the negative charge from a power supply, which charges a swirling jet of gas from the distributor, changing it to plasma. The nozzle constricts and focuses the plasma into a jet, while the shield protects the nozzle from spatter and debris. Thanks to advances over the decades, these individual parts have been improved to decrease wear and tear and improve output.

4. A PAC power supply

Today, boost inverter power supplies are used in cutting HVAC components due to their sophisticated microprocessor controls. These controls help modulate the power supply, combatting any variations in voltage while consuming less power. This makes them more robust than older inverters and insulated gate bipolar transistors (IGBT) that used to be standard.

5. A mechanical plate follower

A plate follower is a shroud that surrounds the cutting torch. Ball casters allow it to roll gently over the cutting material. It serves two main purposes: to protect the torch from crashing into obstructions and to keep it at a regular height.

However, when cutting or piercing material 1/8-inch or thicker, the plate follower is replaced with an automatic voltage-regulated torch height control (THC) system. These automatic systems regulate torch height.

6. A downdraft air table

Most cutting tables for HVAC production use downdraft air tables to maintain clean and dross-free cutting spaces. These negative pressure systems pull any smoke or debris created during manufacture down and away from the cutting surface.

Related Posts: All About Plasma Cutting Accessories and Why You Need Them

Recent Developments in HVAC Plasma Cutting

Developments for HVAC plasma cutting parts and techniques are happening all the time. In the last few decades, the production of HVAC components has changed drastically. Some more recent additions to these machines include:

Contact Starting – Traditionally, plasma torches were ignited using a bug-zapper transformer and spark gap. This method, however, created a degree of radio frequency (RF) noise that could affect the machinery. Contact start torches have replaced these by providing a high-voltage spark that initiates the plasma torch. This lowers the amount of RF interference while improving startup reliability.

High-Flow Shield Gas – Newer forms of shield gas increase the amount of energy output by the plasma jet. These proprietary gas systems provide a high-momentum axial jet that encases the plasma jet. Its purpose is to quickly and efficiently remove excess material from the kerf around a cut, improving the overall cut quality and sparing any cleanup.

Quick Disconnect Torches – Modern power supplies allow for much quicker removal and attachment of torches, making removing damaged or worn torches or switching to manual cutting significantly quicker with no disruption.

Auto Voltage – Inverter power supplies created for PAC use can now handle and alternate between different power inputs. By automatically adjusting to the input power, HVAC production machines can run different components or on different power sources without the need for costly rewiring.

HVAC production has seen only great improvements since the introduction of plasma cutting. The future also holds further potential improvements, so expect more HVAC unit manufacturers to embrace CNC plasma cutting machines.