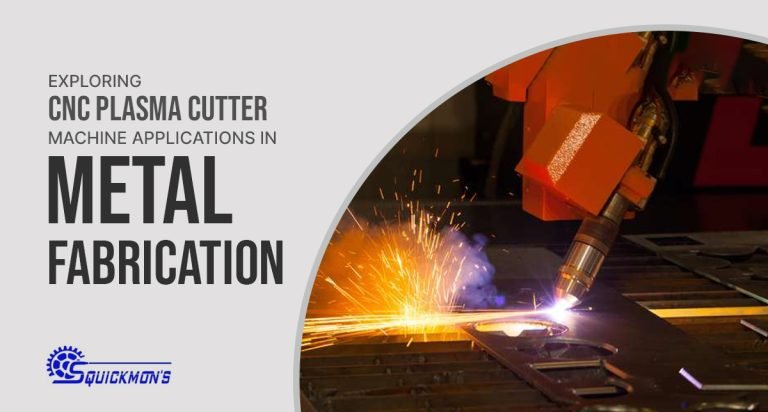

Plasma Cutting Process: How It Works, Pros & Cons

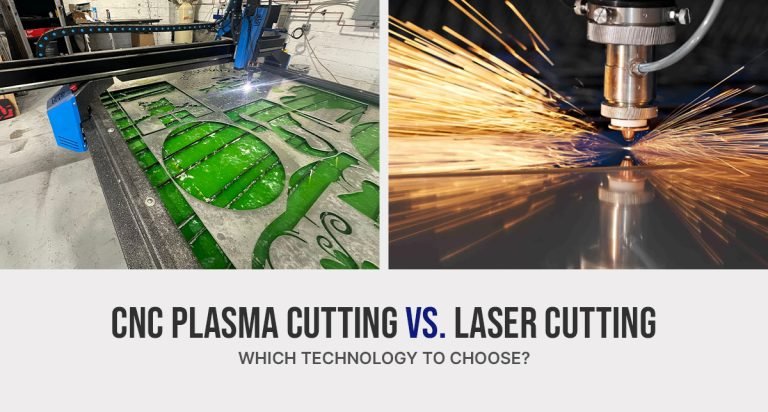

Plasma cutting is an advancing modern manufacturing process. It offers a precise method to cut through a range of metals. That too at a high speed. Given the benefits that this technique has to offer. It is preferred over the various traditional techniques. Such as laser and water jet cutting that were applied for cutting through metals.

What is Plasma Cutting?

It is essentially a process that makes use of an accelerated jet of hot plasma. To cut through conductive materials. It is extensively used for cutting steel, aluminum, brass, and others.

The development of the first such cutting torches dates back to the mid 1900s. These devices were then quite expensive and bulky. However, they offered many advantages. Over time the equipment has become affordable, efficient, compact, and durable, as a result of which it is widely used across different industries.

How Plasma Cutting Works

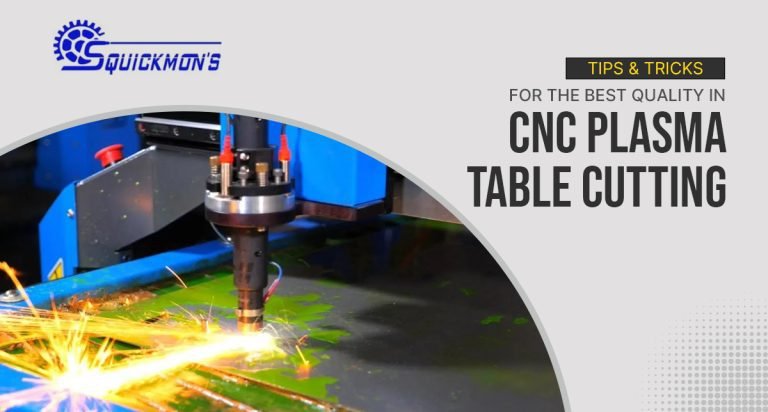

Plasma cutting makes use of plasma, a state of matter created with ionized gas. It not only conducts electricity but produces intense heat. When it comes to understanding the cnc plasma cutting machine system. Its main components happen to be:

- Plasma torch: With a nose and an electrode, this component usually directs the plasma arc onto the material that is to be cut.

- Power supply: This system usually delivers the electrical energy required to create and sustain the arc of plasma in a cnc plasma cutter.

- Ground clamp: It is a component that helps make sure that the plasma arch remains focused upon the cutting area. It is usually connected to the work piece to complete the electrical circuit.

- Control unit: This component regulates the operation of the cutter, allowing for precise control over the process.

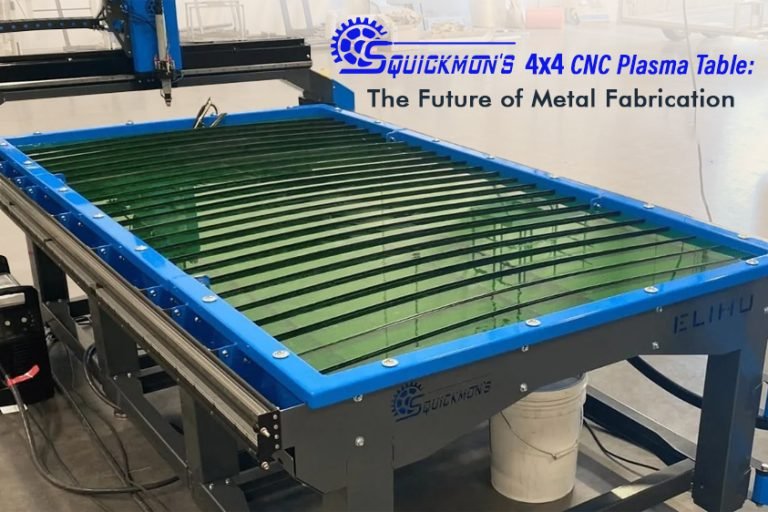

Adding more parts, such as a plasma table, can make the process more efficient.

The step-by-step process can be better understood in the following ways:

- Ionization of gas

In this step, a gas is passed through the plasma torch. It can be nitrogen, oxygen or compressed air. An electrical arc created between the electrode and the nozzle allows for the gas to be ionized.

- Creation of the plasma arc

The ionized gas in its plasma state is usually forced through a small opening in the nozzle at an accelerated speed. This forms the plasma arc, which reaches extremely high temperatures and is suitable for precise cutting.

- Cutting through the metal

In the last step, the arch is directed onto the metal that is to be cut.

Types of Plasma Cutting Systems

- Conventional plasma cutting systems

These systems are quite well suited for general-purpose applications, and they find extensive use in industries for their versatile and cost-effective approach.

- Precision plasma cutting systems

These systems are usually designed for applications that require extreme accuracy, high precision and versatility. They produce smooth cuts with tight tolerances, making them ideal for intricate work.

- High-definition plasma cutting systems

These systems are found to be extensively useful when superior cut and precision are required. In terms of accuracy and quality, these rival laser-cutting approaches as well.

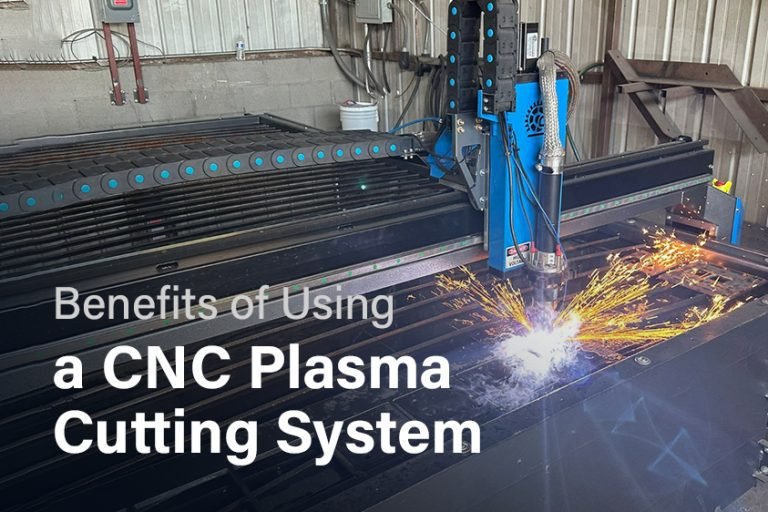

- CNC plasma cutting systems

These systems are controlled by computer software and are usually automated. The plasma cutting software facilitates the use of the device in complex cutting approaches that are carried out in repetition and require precise cuts.

Advantages of Plasma Cutting

- Precision: This approach can help make clean cuts with minimal thermal distortion, making it ideal for detailed and intricate work.

- Versatility: Plasma cutting can be put to use for a range of conductive metals, regardless of their thickness.

- Speed: The approach is much faster than the various traditional methods. Each can save time and carry out the cutting efficiently.

- Cost-effectiveness: This modern technique is quite affordable and requires low operational costs compared to other traditional approaches.

- Safer approach: The systems use inert gases, which are much safer than oxygen-based cutting, which carries a risk of explosion. The availability of components such as the cnc plasma table can be additionally quite helpful, depending on the approach.

Also read: Plasma Cutting Gases: Types And How To Choose

Disadvantages of Plasma Cutting

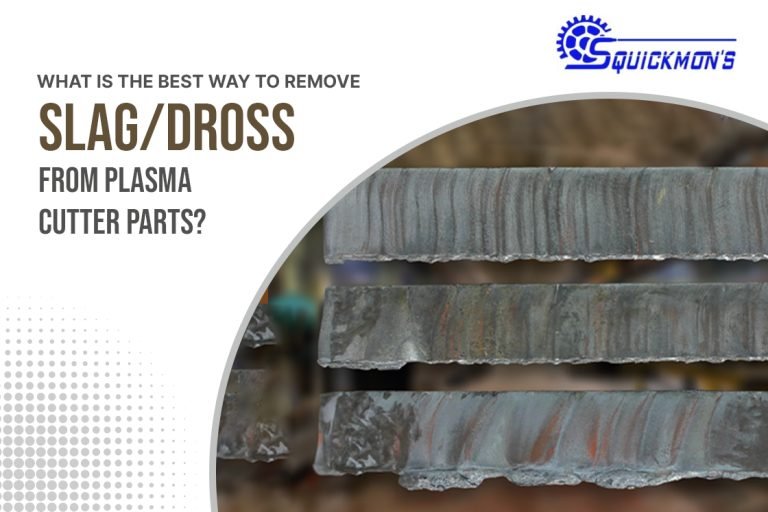

- Noise and fumes: This process generates much noise as well as fumes, which necessitates proper ventilation and hearing protection.

- Investment costs: The cost of setting up this system can be high, despite its maintenance being relatively cheap.

- Operating costs: Parts, such as electrodes, nozzles, and plasma cutting table that require replacement can incur additional costs.

Conclusion

Plasma cutting is a process that is both versatile and highly efficient. It offers many advantages and has revolutionized the way industries approach metal cutting. It greatly improves the way production processes are optimized and helps improve the quality of products. It is allowing industries to grow and play an important role in the process of manufacturing, bringing about a revolution in the same. If you seek ‘plasma cutting services near me,’ you have come to the right place! Trust Squickmons to cater to your plasma cutting needs, from quality plasma cutters to cnc plasma cutting table. They have it all! Visit https://squickmons.com/ to know more!