LEADING THE INDUSTRY

IN SUPPORT & WARRANTY

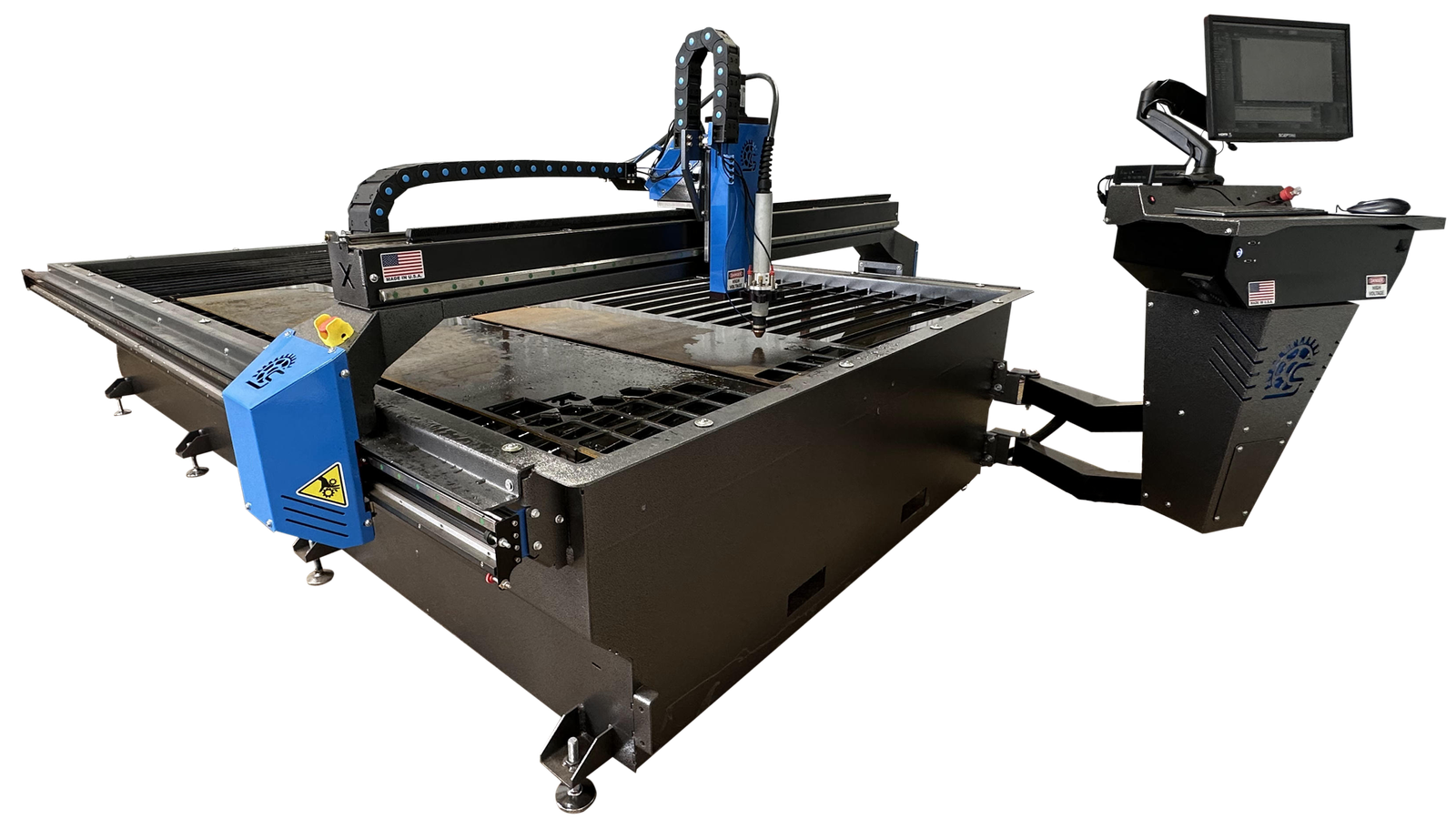

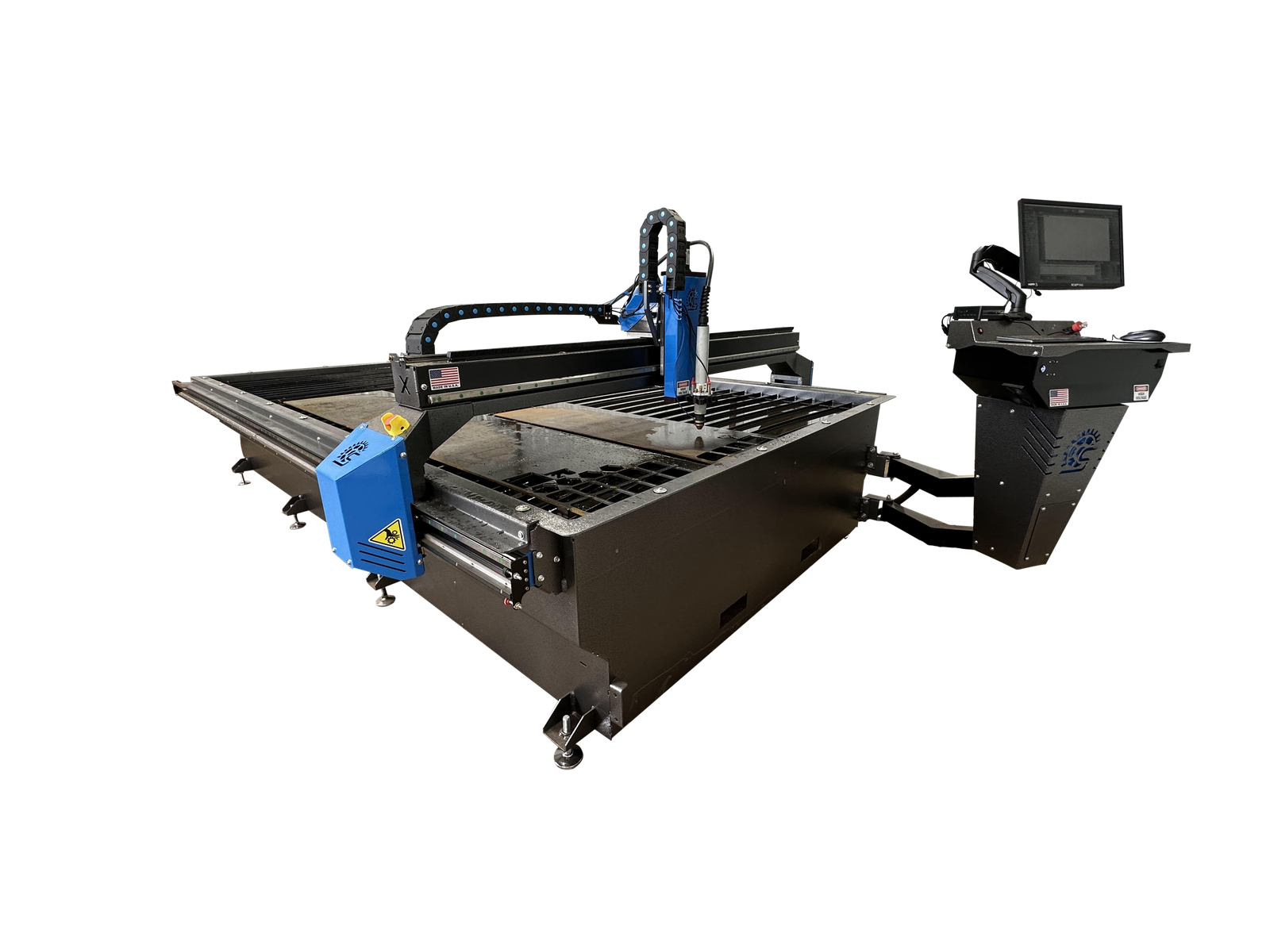

Introducing the Elihu HD Series with a 15,000 lb

load capacity an advanced software

ALL ELIHU HD SERIES SYSTEMS INCLUDE :

- All-In-One CNC Interface

- Ohmic Sensing (Probe zero sensing)

- Collision Detection Head (includes torch squaring and integrated floating head proximity sensor)

- Z-Axis Lifter 6.5″ (Provides 6.5″ of Z-axis travel)

- 5 Year Warranty on all CNC electronics

- 5 year Warranty on all Mechanical Components

- Lifetime Tech Support

Optional

- Intel NUC PC i5 Processor upgradable to i7 Processor

- Arc Professional – All In One Software (CAD, CAM, CNC)

- 2 PC Software Licensing

- ELIHU PC Pedestal with integrated serge protector and wire shielding (Recommended)

- Rotary Axis Gantry (Including Lathe Chuck (4″, 8″, and 16″ available)

- Air Bladder with water level adjustment (used for small part removal, maintaining proper water level, and machine clean out)

Request A Quote

BUILD YOUR SYSTEM

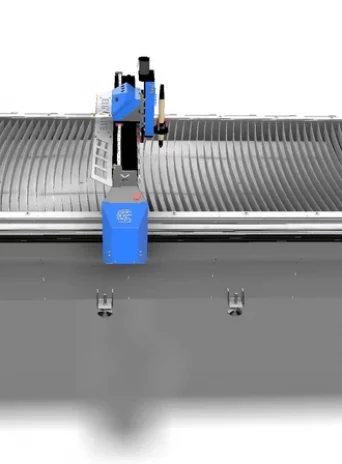

Design Feature:

- 6.5" Z-Axis Travel

- 6.5" Gantry Clearance

- 3:1 Motor Reduction

- Precision Ground Linear Rails

- 4" Anti-slip Leveling Feet

- Enclosed Cable Track

- 3 Axis Protective Enclosures

- Water Table

Control Feature:

- Anti-collision Safety System

- Electronic Height Sensing

- Floating Height Sensing

- Homing Switches

Squickmon’s machine orders placed today are estimated to ship in 2-3 business days. You are entitled to a full refund minus a 2.4% transaction fee until your order ships.

TALK DIRECTLY TO ONE OF OUR PRODUCT SPECIALISTS

Info@Squickmons.com

Hypertherm

- Powermax 45XP, Air, 45 Amps

- Powermax 65, aAir, 65 Amps

- Powermax 85, Air, 85 Amps

- 3 Phase Only

- Powermax 105, Air, 105 Amps (208V)

- Powermax125, Air, 125 Amps (480V)

Victor thermal dynamics

- Cutmaster A40 45XP, Air, 40 Amps

- Cutmaster A60, Air, 60 Amps

- Cutmaster A80, Air, 80 Amps

- Powermax 120, Air, 120 Amps

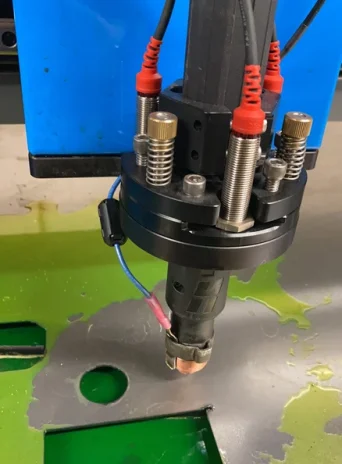

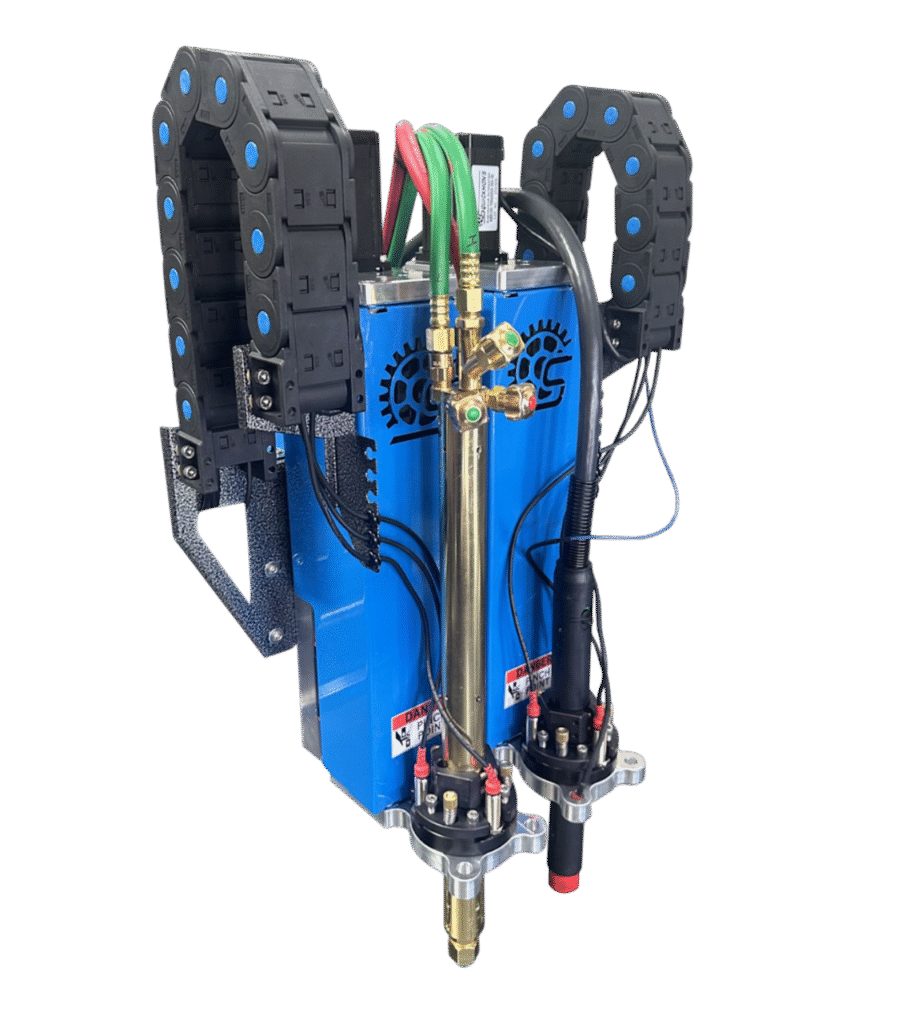

Z-AXIS FULLY INTEGRATED MULTI-PROCESS:

- Slim Linear Actuator Design (Increasing Cutting Area)

- 6.5″ Lifter Height (Included on all HD Series)

- Internal Wiring Harness Sub Assembly (For easy diagnosis and repair)

- Integrated Multi-Process Pneumatic Actuator Scribe and Marker

- Protective Front Enclosure (Covering linear components and Pneumatic cylinders)

- Rear Enclosure Protection (Covering Motor Reduction System)

- Enclosed Cable Carrier (Assisting with management of collision detection wiring and pneumatic hoses)

- Scribe & Marker Compatible (Available only for Arc Professional Software Package)

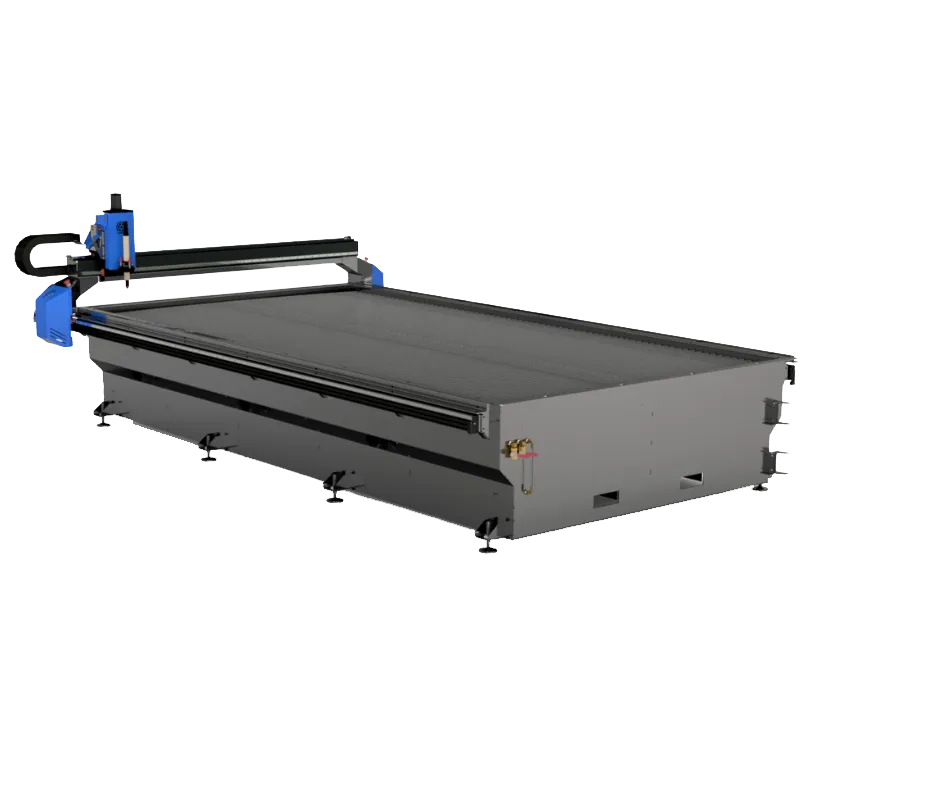

FULLY WELDED FRAME DESIGN

- Fully Welded Frame Design (constructed from 3/16 plate)

- Rigid Design To Counteract Vibrations and Inertia

- Dropped Side Rail Design for 3 Side Material Loading

- 6″ Deep Water Pan

- Recessed Transfer Rollers On All 4 Sides (For Material Loading)

- 4″ Diameter Leveling Feet With Rubber Pads (3/4-11 Thread)

- Machined gear rack mounting surface (Easily replaceable)

- Extended Frame Along Y-Axis For Gantry Parking Zone

- Removable / Replaceable Slat Holders

- Optional Air Bladder available with holding capacity of 2 times upper pan capacity.

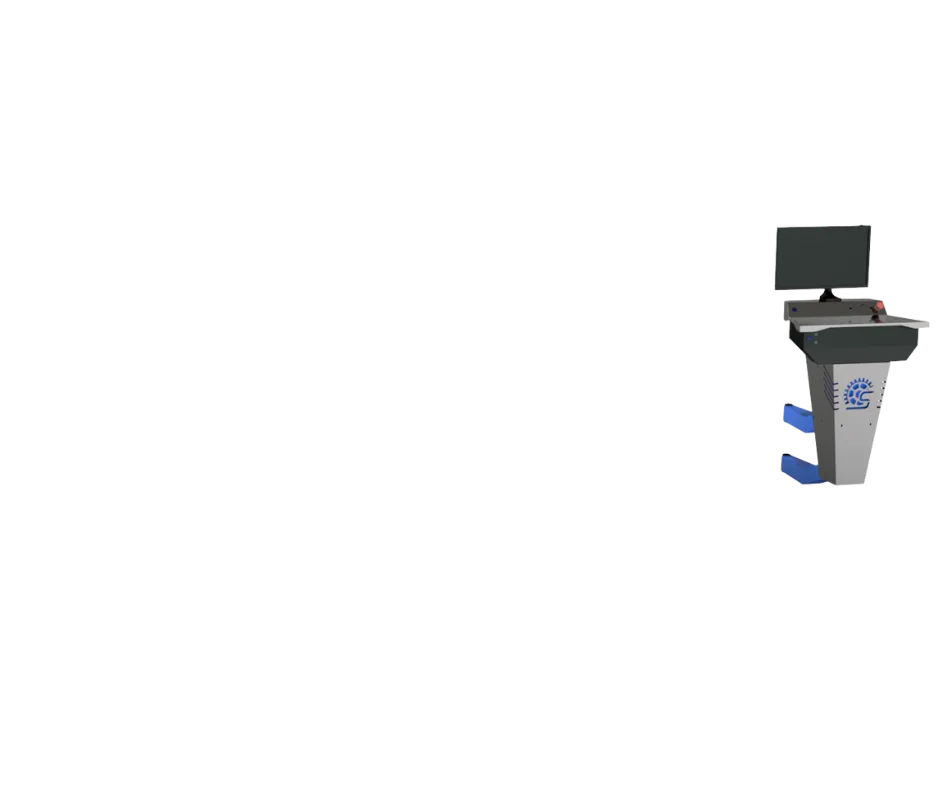

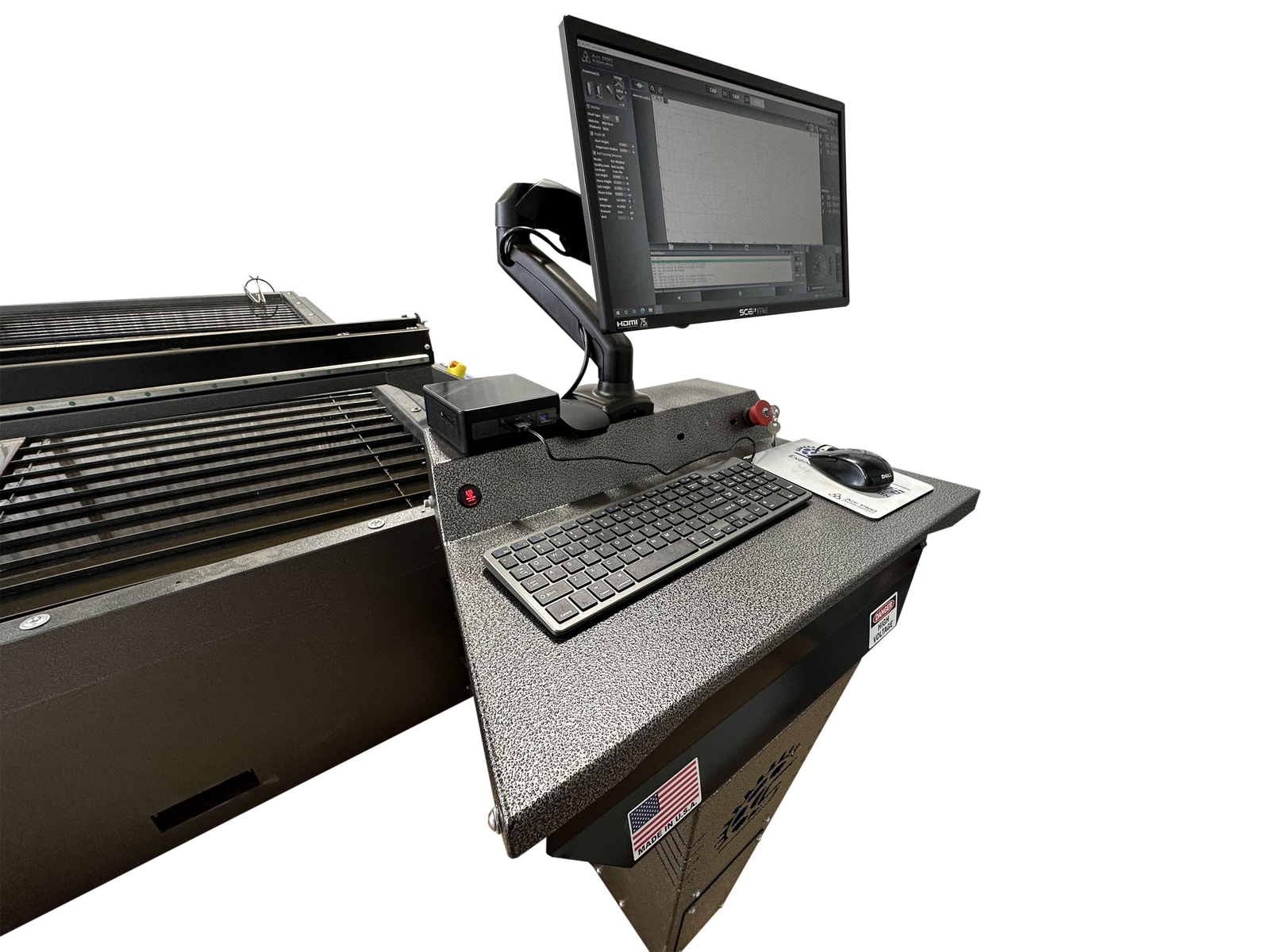

COMPUTER STATION & PEDESTAL OPTION

- 225 Degree Pivoting Pedestal Arm Rotation

- 360 Degree Monitor Rotation & 10 inch Height Adjustment (Allowing for Easy Screen Viewing Angles and Ergonomic Screen Placement)

- Full Enclosures With Easy Wire Harness Routing

- Wiring Harness Protection and Consolidation

- Hidden 3 Receptacle Power strip

- Integrated Emergency Stop and Torch ON/OFF

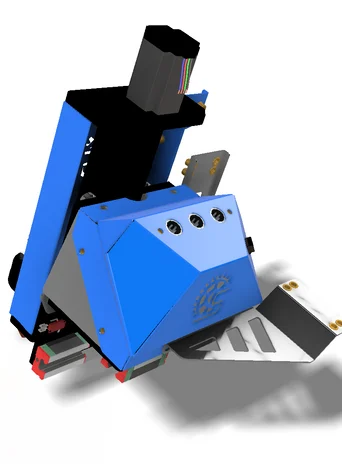

COLLISION DETECTION HEAD-ASSEMBLY

- 2 Axis Squaring For Torch Setup (Referred To In Hypertherm Manual)

- Dual Collision Proximity Sensors (Allowing For Program Stop Within 2 Degrees Out Of Alignment)

- Front Floating Proximity Sensor (Secondary Touch Off Option If Ohmic Fails To Sense Material)

- Indexing Cones Design (Provides Torch Relocating of True Position)

- Unique Hexagon Geometry (Unlike Competitors Our Collision Detection Head Is Designed And Manufactured By Squickmon’s in the USA)

- Integrated Positive Z-Axis Homing (No Material Loading Required For Homing)

Dual Z-Axis Lifter:

- Dual lifter option is available in 7” & 9” travel options

- Both lifters offer collision detection and floating head switch

- Works along side our multiprocess Z-axis scriber and marker option

- Allows for part marking with powermax45 Sync occupying secondary lifter. Fast part marking with no tool changer.

- Allows for Max Pro 200 or Oxy Fuel setup

- Works along side our Multi-Shape Tube cutting attachment for marking and cutting tubing.

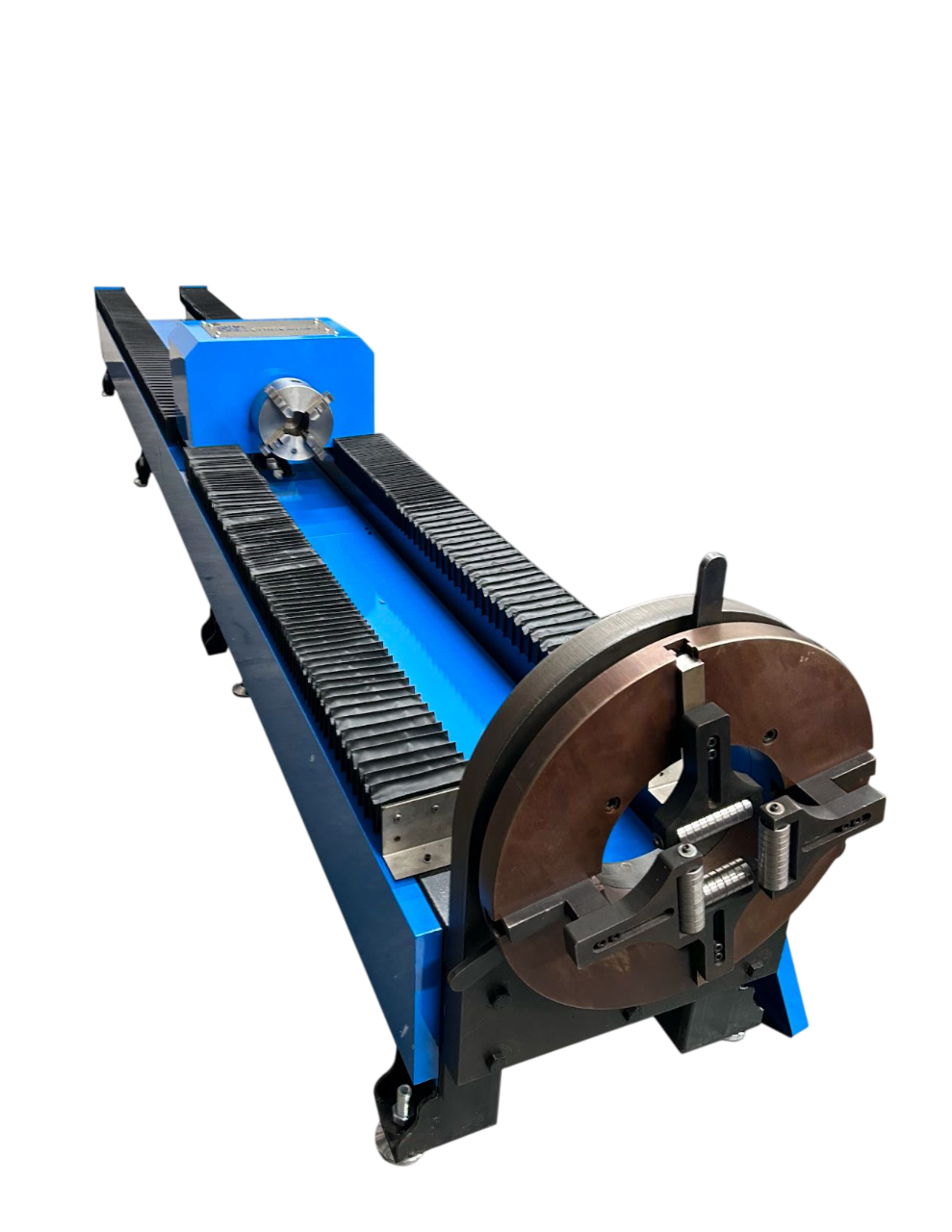

Multi-Shape Tube cutting attachment:

- Available in 12ft-24ft

- Tube feeding function allows you to process 24ft tubing along side a 4X4 cutting table.

- Process round or Square Tube up to 12” (dual drive chucks required on systems over 6” in diameter or over 12’ long.

- Works along side our multiprocess Z-axis for tube and pipe marking or scribing.

- Limit switches for both positive and negative directions.

- Includes machine homing

TABLE CONSTRUCTION AND SIZE OPTIONS :

- All Elihu HD Series Systems are Offered in the Sizes Below

- 4X8 5X10 6X12 8×16 8×20

- Machined .625″ T6 6061 Aluminum Gantry Side Plates

- Hiwin Style Linear Rail System Across X & Y-Axis with Recirculating Ball Bearing Cassettes (Creating Smooth Linear Motion)

- 15,000lb Loading Capacity (For processing material from 26g – 6″ Plate)

- 2″ Slat Offset (Helps with tipped parts when Cutting)

- 6.5″ Gantry Clearance (Beneficial When Cutting large part profiles, beams, and tubing)

- 16g Steel Gantry Enclosure Protection (Guards motors And reduction assemblies from impact)

- Adjustment for Gantry Squaring and Homing Switch Positions

- 3/16 Fully Welded Steel Frame (Extremely Rigid)

- All Elihu HD Series Systems are Sized To Fit A Standard Sheet Width Relative To Their Designated Machine Size Plus 6″ Oversized For Cutting Area (Example a 4×8 Machine has a minimum of 54″x100″ Cutting Area)