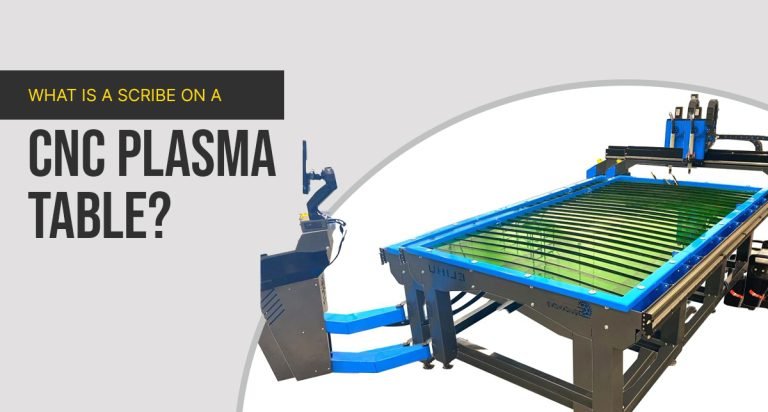

What is a Scribe on a CNC Plasma Table? Uses and Benefits Explained

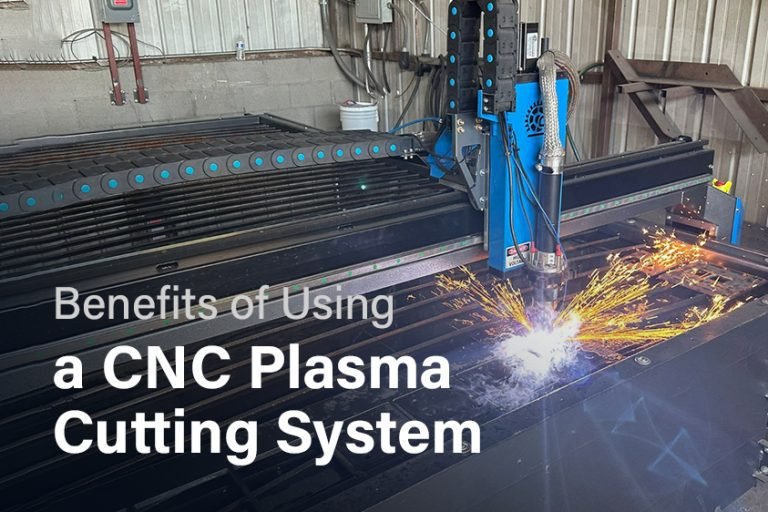

Introduction

A CNC plasma table scribe is an essential tool in the metal fabrication industry used primarily for marking, scoring, and engraving on various materials. Unlike the traditional cutting of materials by plasma, in the scribing process, one leaves shallow and controlled marks that do not cut all the way through.

The use of scribes on CNC plasma tables, which the industry has advanced into today, plays a critical role in manufacturing and fabricating. The precision marking and engraving manufacturers can make on their materials also add accuracy to their work when assembling or welding.

As we discuss how it operates differently than traditional cutting, let us discuss its application, advantages, and limitations. Enter the universe of CNC scribing to gain a better understanding of the significant value it creates.

What is a Scribe Tool?

Describe Scribe Tool

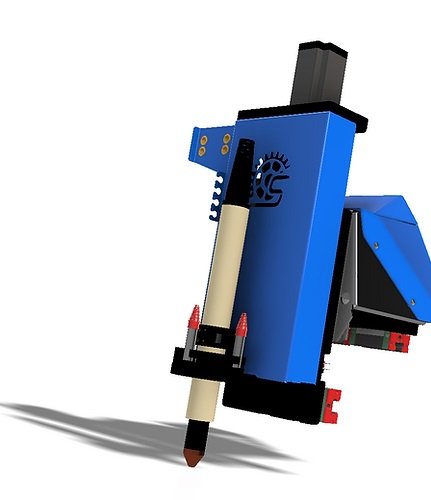

A scribe tool is very much like a pencil on paper but uses a hardened metal tip etched into the surface of the material to stamp out designs or marks. It is not cutting like a plasma cutter or torch; rather, the scribe uses its tip simply to etch shallow markings that will serve as guides for further operations, such as cutting, bending, or welding.

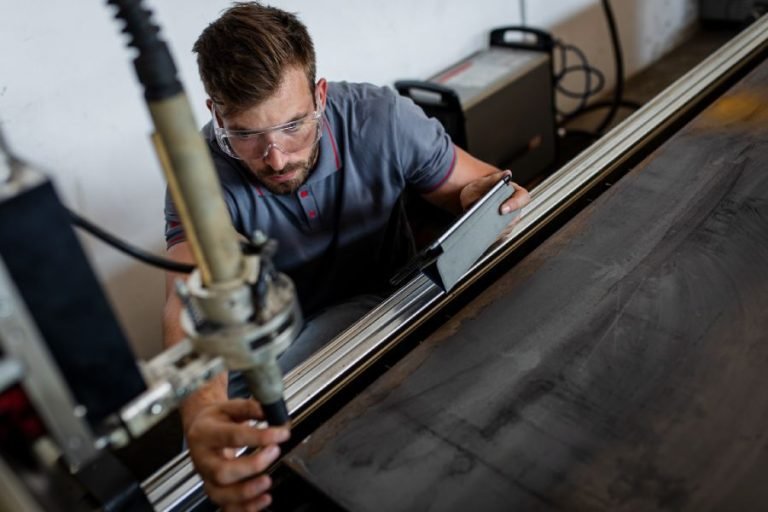

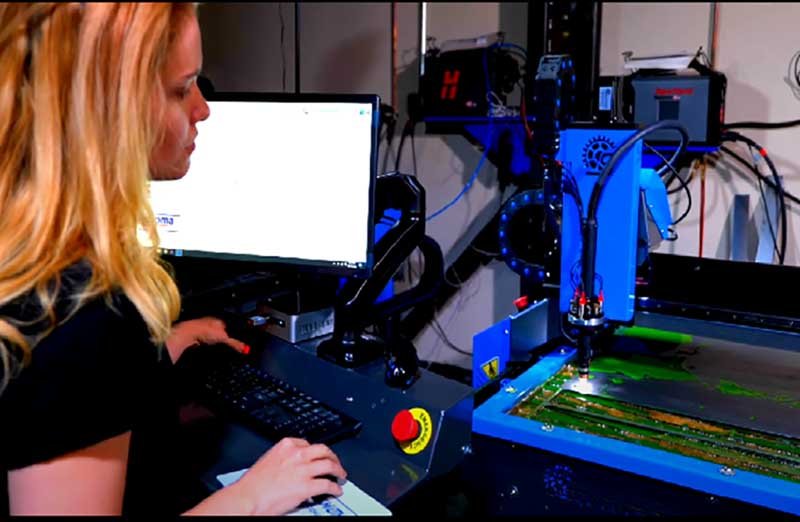

The CNC scribe setup is generally straight forward. The scribe tool is mounted to the plasma torch on the CNC, and with the process flow, it switches between scribing and cutting operations. This duality allows manufacturers to combine both operations in a single workflow without having to have separate equipment.

Comparison to Traditional Plasma Cutting Tools

A scribe does not cut the material like a plasma cutting torch would, cutting through metal with an electric arc and compressed gas. A scribe uses direct pressure to mark the material. Plasma cutting is ideal for removing material; the opposite holds for scribing – it is perfect for precise marking, engraving, and outlining.

The other variation between the two methods is in the amount of detail and material removal left behind. Scribing doesn’t remove any material but will leave a mark, making it ideal for marking cut lines, serial numbers, or any other reference points that need to be seen with manufacturing.

Key Applications for a Scribe on a CNC Plasma Tables

A CNC plasma table has many uses when scribing on a scribe. Let us now look at some of the primary scribe tool uses:

1. Marking and scoring

The most basic application of a metal fabrication scribe is marking or scoring lines on the surface of materials. Such marks will then indicate places where cuts or welds must be put, thus providing distinct guides for the operators.

- Cutting or welding lines: The scribe marks cut lines to ensure that the materials are correctly cut or welded, leading to low error rates and loss. In industries like the automobile and aerospace, where there should be no room for mistakes, it is very critical.

- Position references for robotic systems: Such markings may be a critical factor in highly automated environments as they will enable robotic arms to pick the positions to apply the cuts, bends, or welds.

2. Product Identification

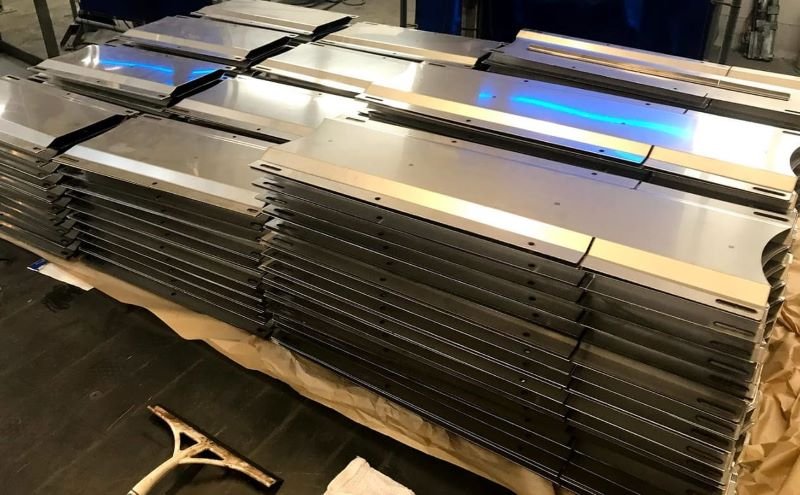

Another important application of a CNC plasma table scribe is CNC plasma part marking. The scribe can punch numbers, serials, or any markers into a material precisely.

- Etch serial and part identifiers: It is widely used to enable traceability of parts during the manufacturing and assembly processes. This etched information makes it easier to carry out the manufacturing processes as workers can easily identify and sort out parts.

3. Design Preparation

The CNC plasma marking also very well suits design preparation. A scribe can etch an outline of the design right before one piece is cut, formed, or machined.

- Scribing outlines to be further cut or machined: Outlines serve as guidelines for further works. The cutting or forming job goes smoother since it acts as a guide. This also proves very effective for complex pieces in which the precision level is very high.

Advantages of a Scribe

One of the advantages of applying a CNC plasma table scribe lies in the fact that there are major benefits that make metal fabrication invaluable. Now, let’s consider some of the major benefits associated with using CNC plasma scribing.

1. Accuracy

The most important advantage of a scribe is to give precision marking. Unlike any other method such as cutting by plasma, scribing provides small details that are etched into the material, especially where accuracy matters a lot.

- Accurate control over marking activities: With the scribing activity, an operator can mark particular locations where cuts or welds are to be made so that fabrication takes place with accuracy.

2. Material is not Touched

Where as plasma cutting will remove the material, a scribe tool marks the surface without touching the material’s integrity. Such is helpful where a producer intends to conserve the base material but has detailed markings to be added to the same.

- More material sparing than cutting: Since there is no burning or removing of material, the work piece is less likely to be damaged or weakened using a metal fabrication scribe.

3. Versatility

A CNC scribe is versatile in that it can work on any material type from metals to plastics. The scribe can be used for diverse applications such as engraving, marking, and preparing design space.

- It can mark up various materials: Whether it is made of steel, aluminum, or softer materials like plastics, a scribe marks equally accurately.

4. Cost-Effectiveness

A scribe tool is also cost-effective because it eliminates the requirement of other equipment such as separate marking machines. This saves manufacturers costs.

- Reduces the need for auxiliary marking devices or methods: Since marking and cutting is integrated into one machine, there is less reliance on various tools and manufacturers work less expensive operations.

Disadvantages of the Scribe Tool

Although it comes with many benefits, a CNC plasma table scribe also lacks several disadvantages.

1. Inability to handle Specific Materials

Some materials have high surfaces and hence hard to get marked in clear traces. Oxidation or debris can cause unclear marks by the scribe

- Some materials problem (mill scale): Materials with surface irregularities or surface roughening agents may require special treatment before scribing so that the marking is clear

2. Surface Markings

Another limitation of a scribe is the superficial marking that can leave impressions that may not be deep enough for durability or readability in some applications.

- Superficial markings, which are not appropriate for all applications, In applications involving deep or highly readable markings, other engraving or plasma cutting may be used instead.

Conclusion

A CNC plasma table scribe is an extremely strong tool that manufacturer’s turn to if they look for precision, efficiency, and cost savings. Be it precision marking or simply product identification, a scribe offers many advantages that enhance the overall quality and accuracy of production. It assists the manufacturer in developing well-detailed, accurate markings, all the while preserving material integrity.

However, there are limitations to the scribe tool in terms of material being processed or when deeper marks are needed. Once the limitations are grasped, then manufacturers can know which tool will fit the job so they may leverage all the benefits of CNC plasma marking.

Improved technology will further advance the technology of scribing, leading to increased utilization of the tool, with increased applications, far beyond the current industries served. Whether in design, manufacture, or fabrication, make sure that the implementation of scribing can fine-tune processes and lead to better productivity.